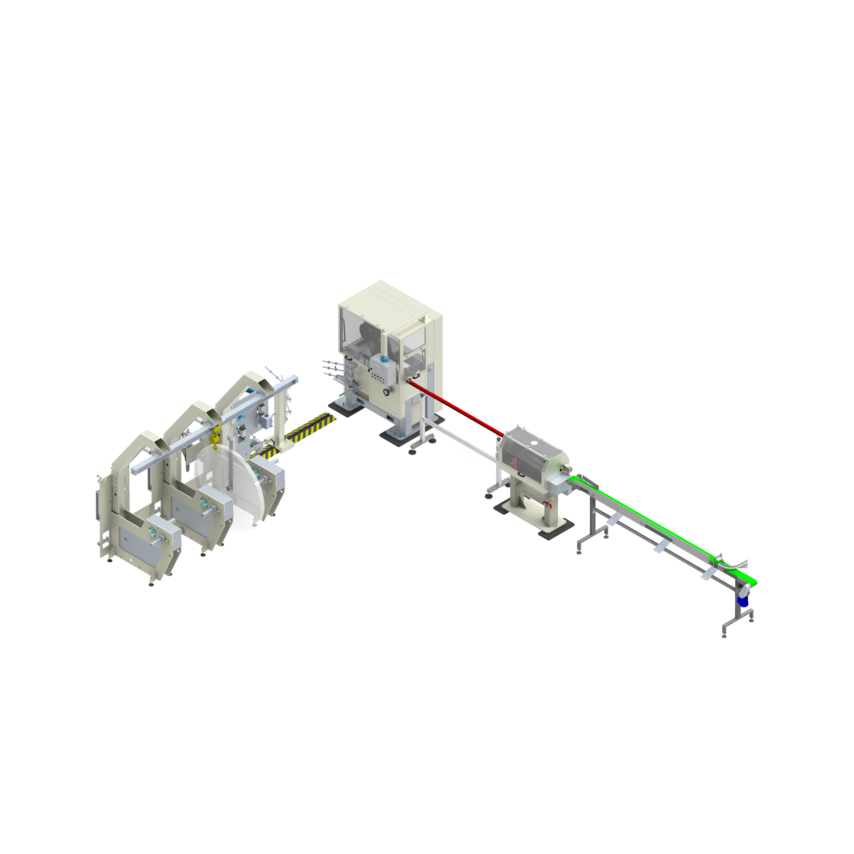

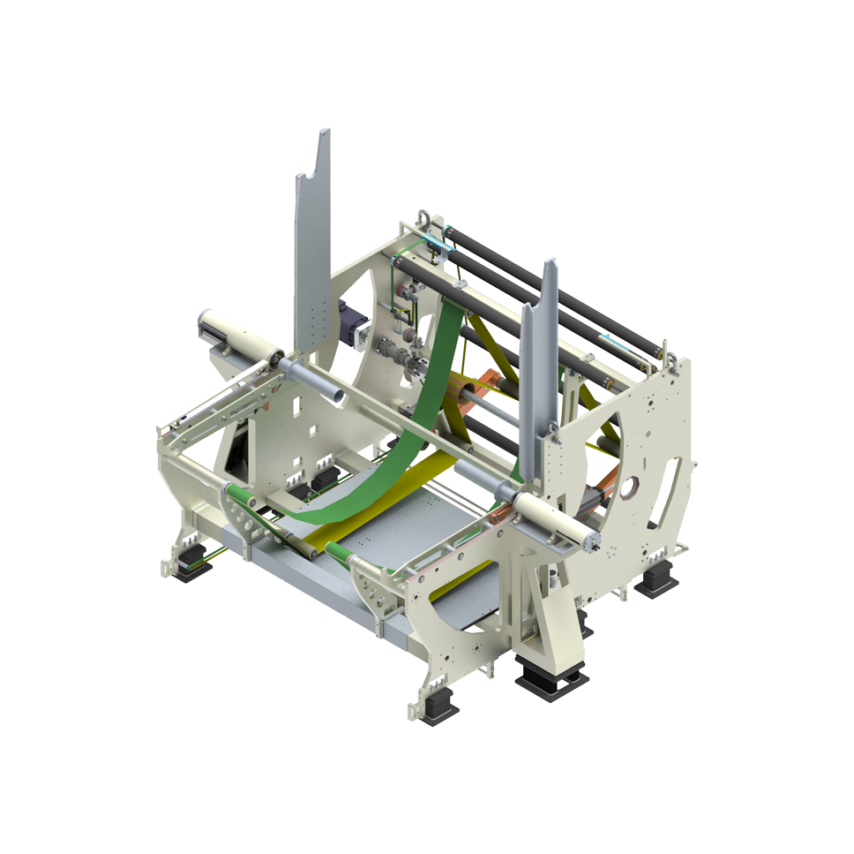

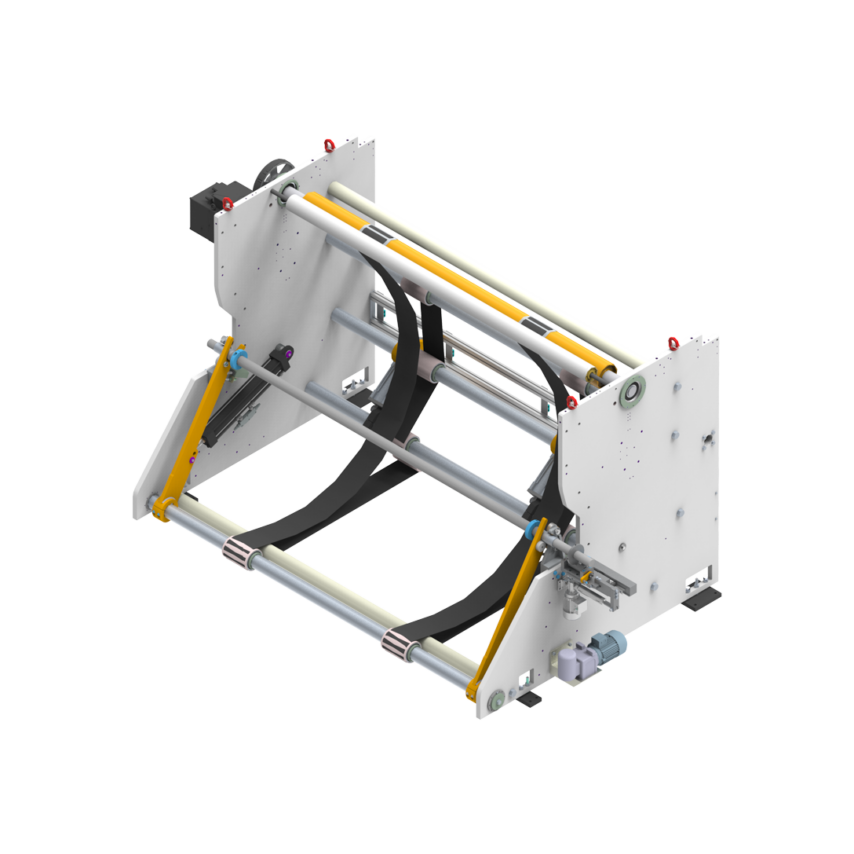

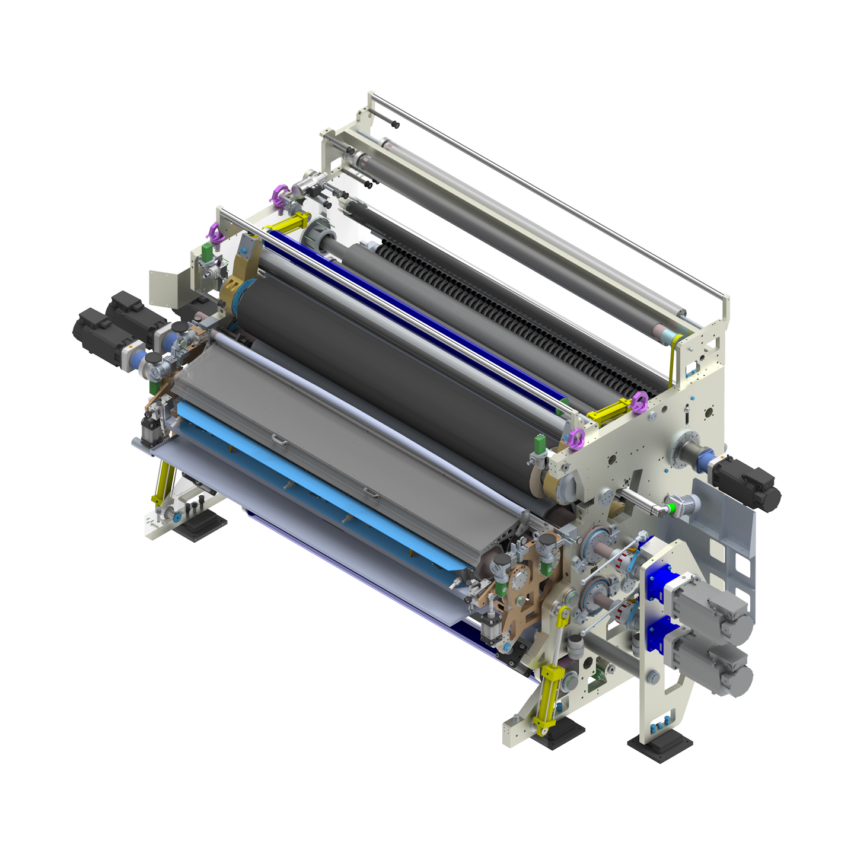

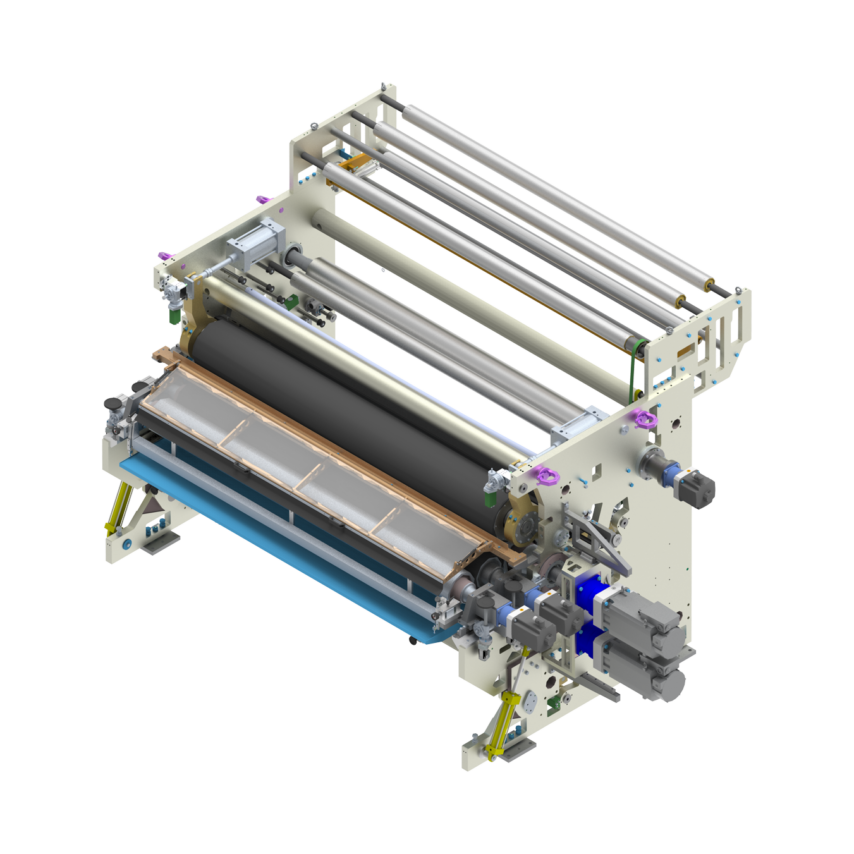

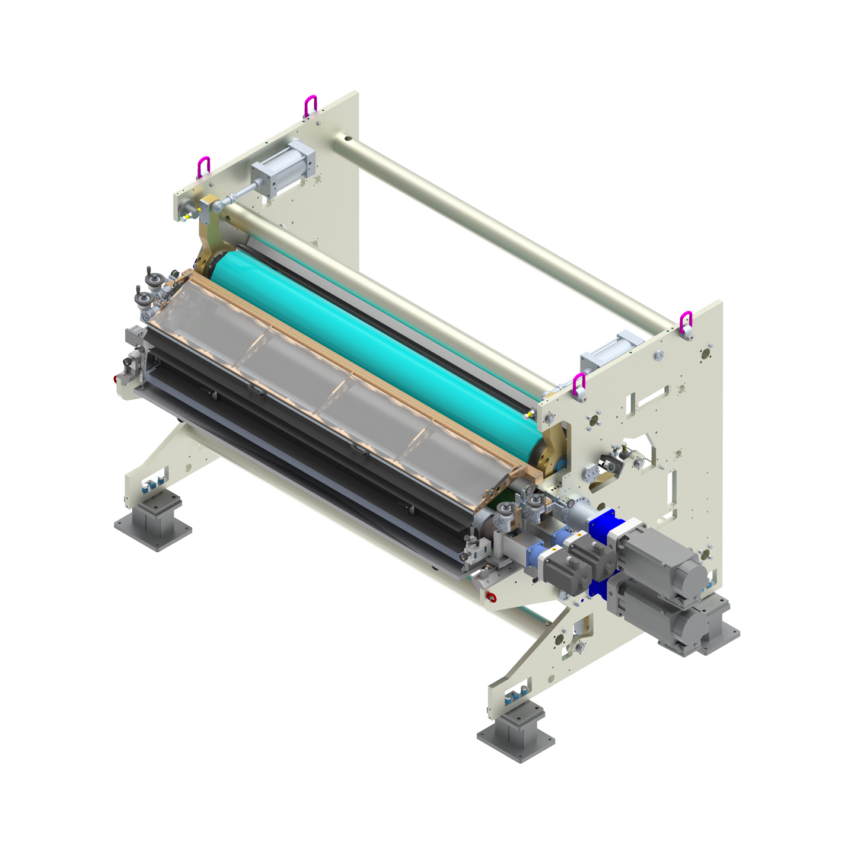

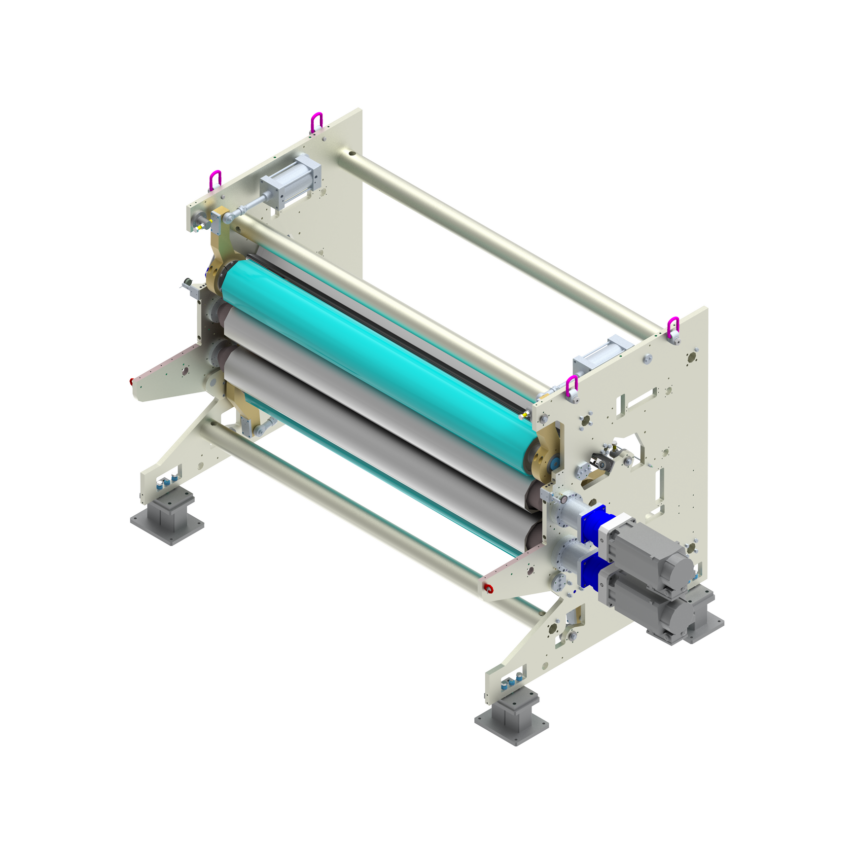

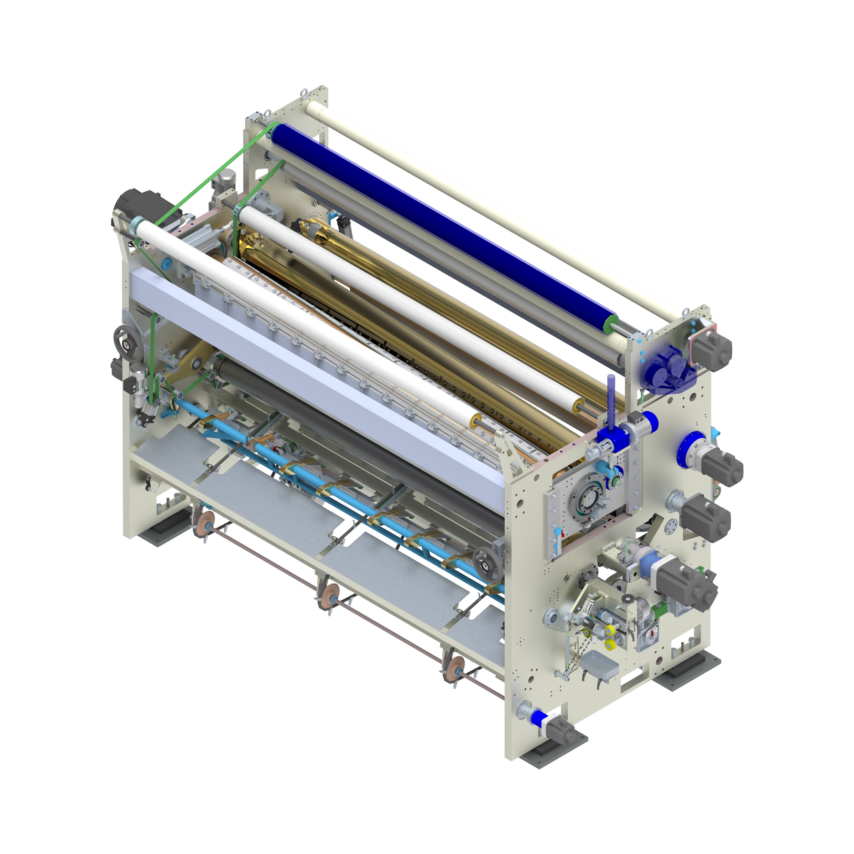

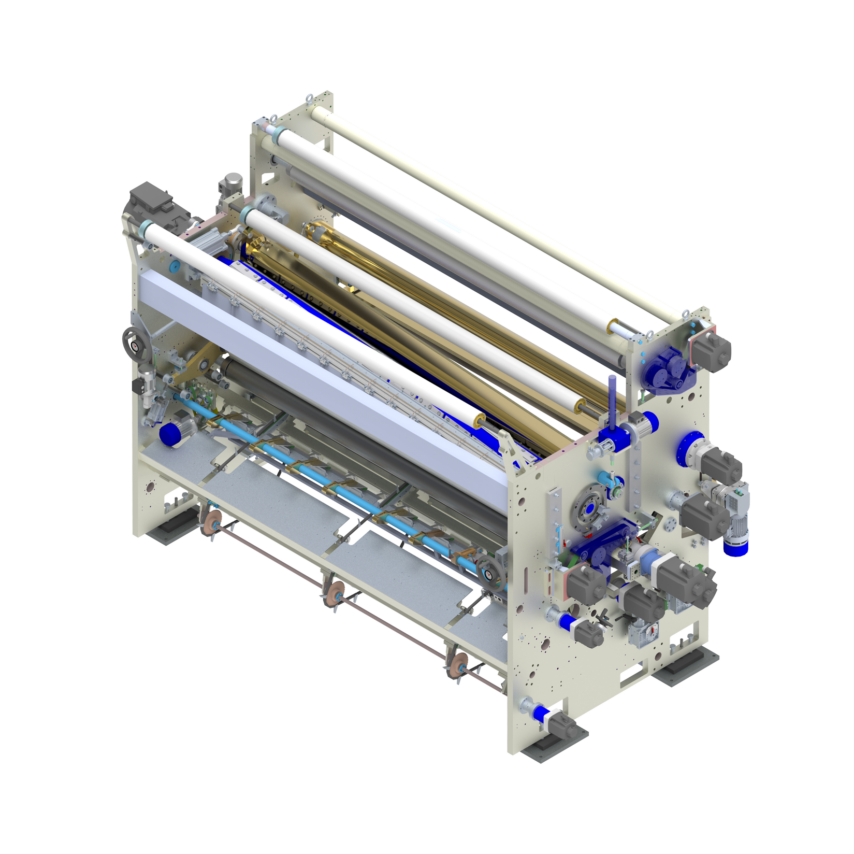

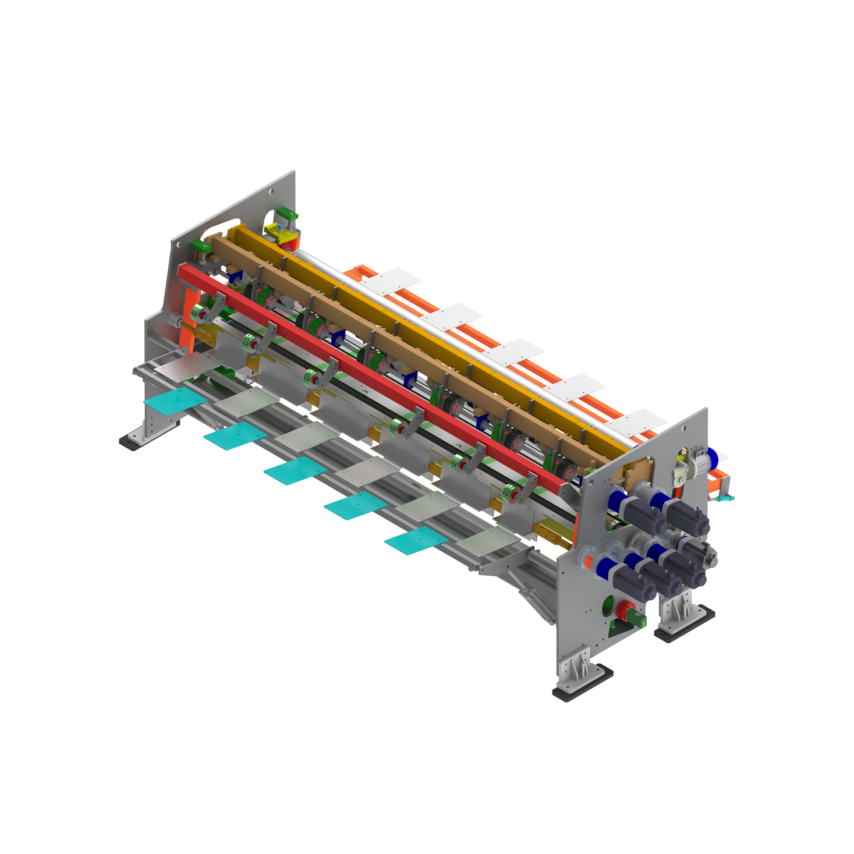

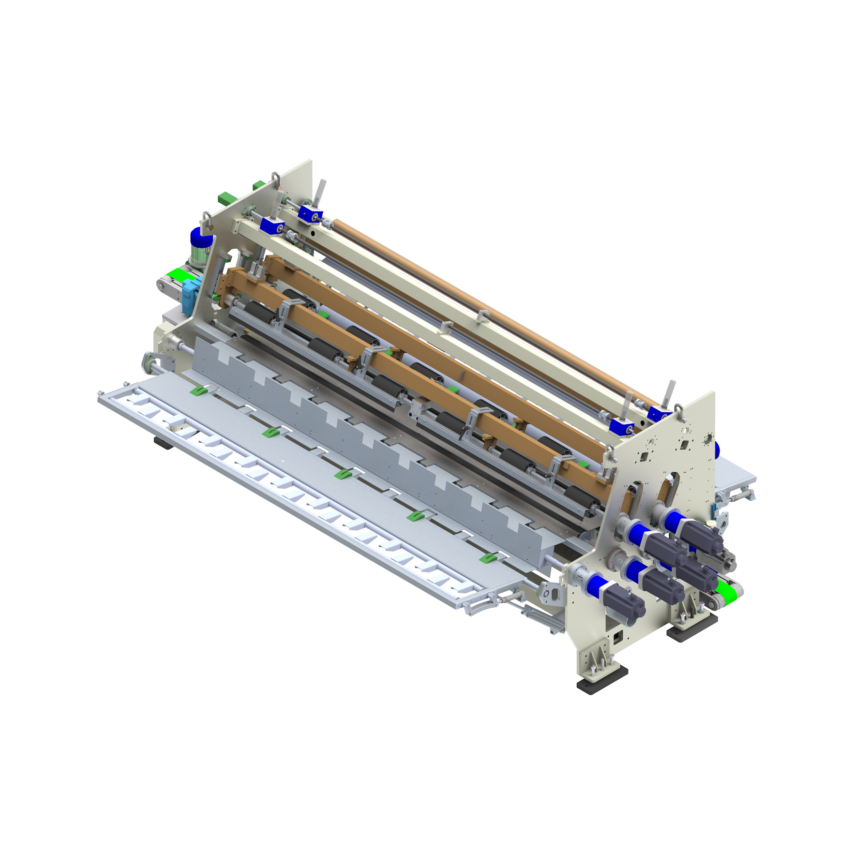

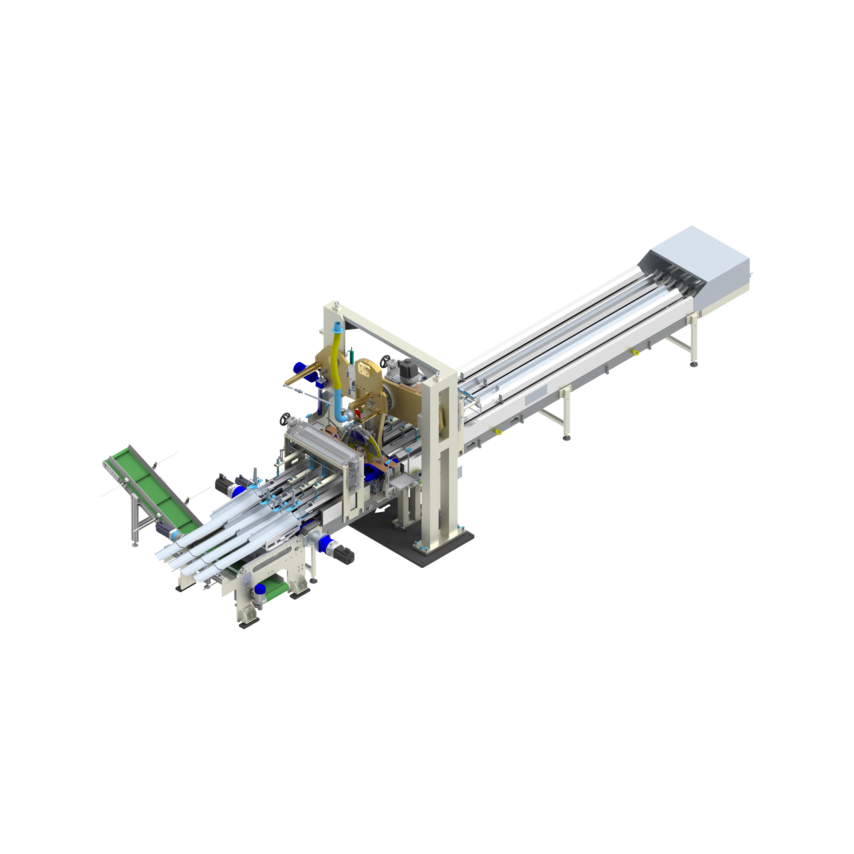

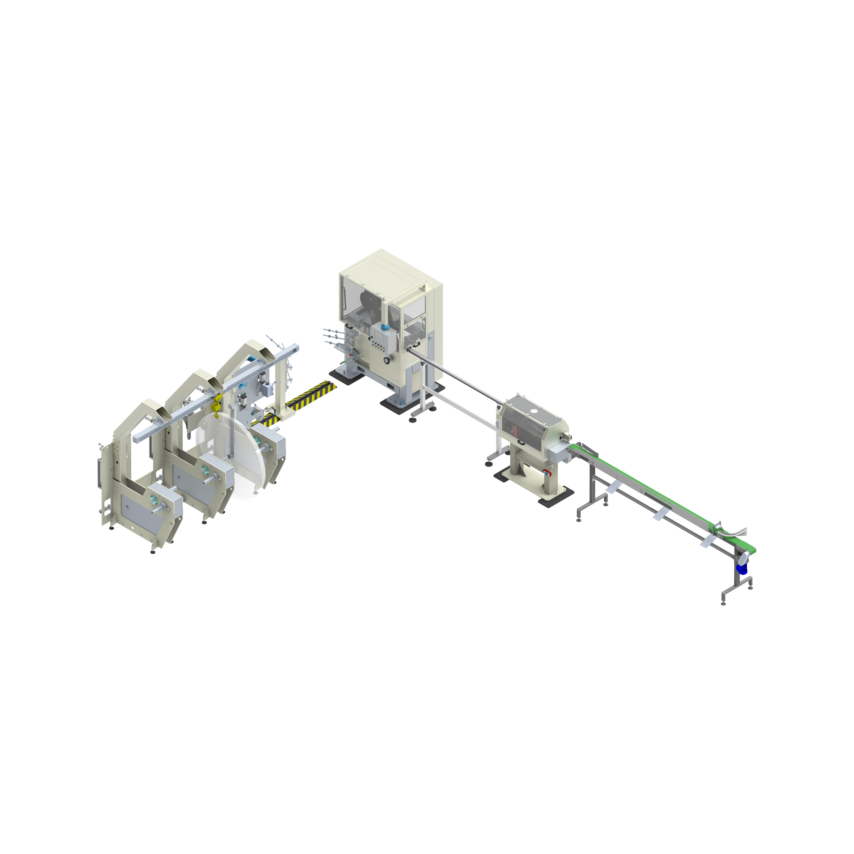

CWC 160C

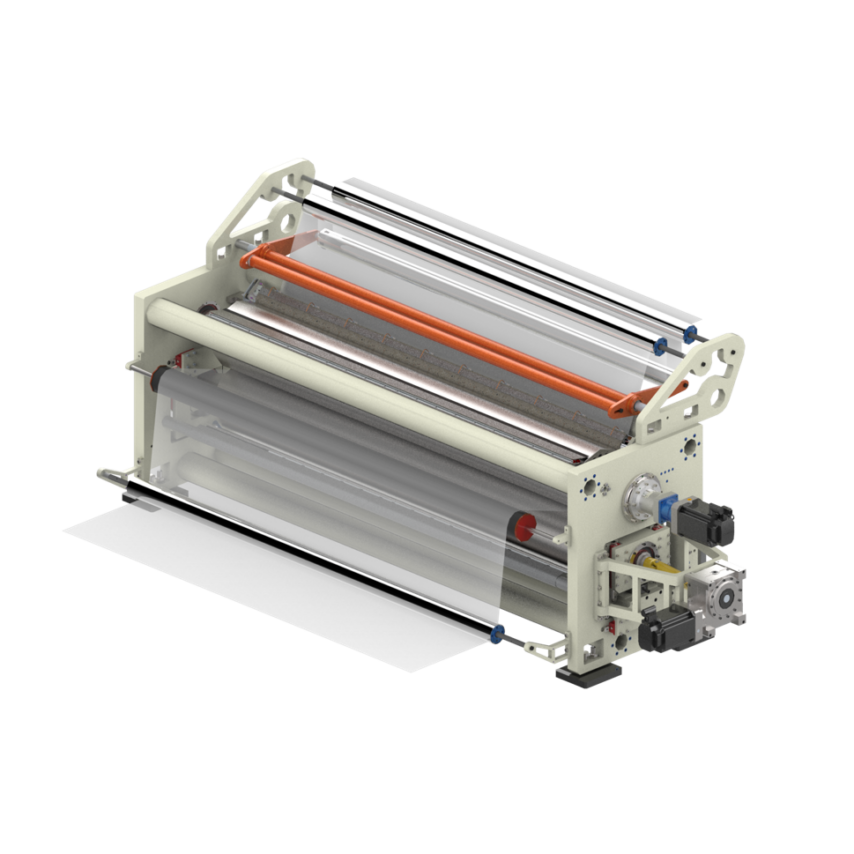

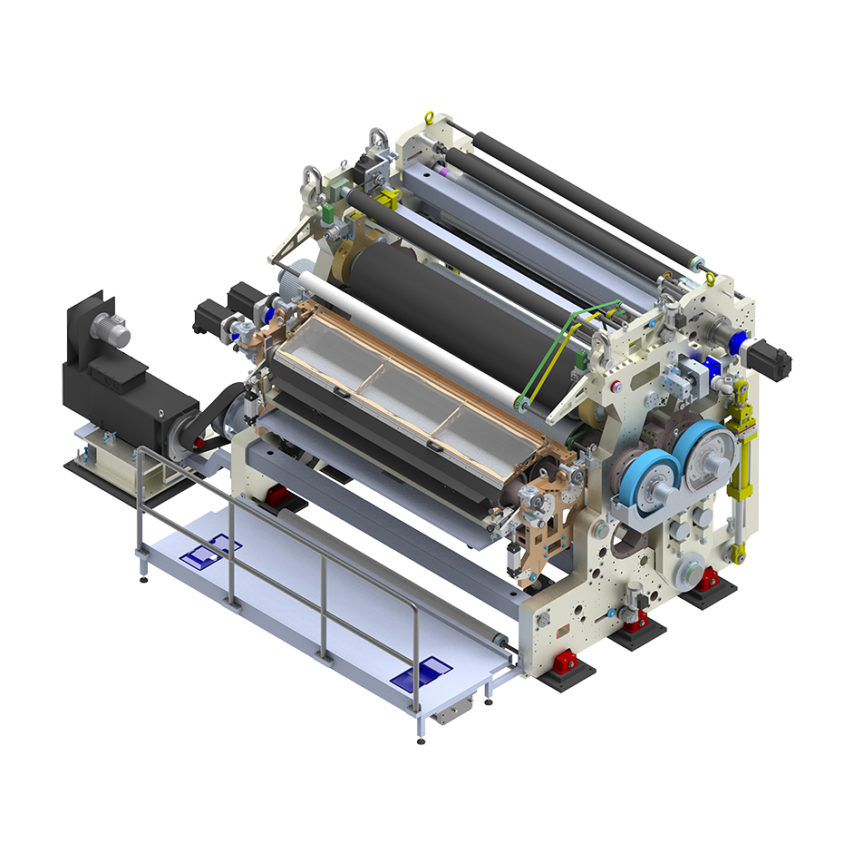

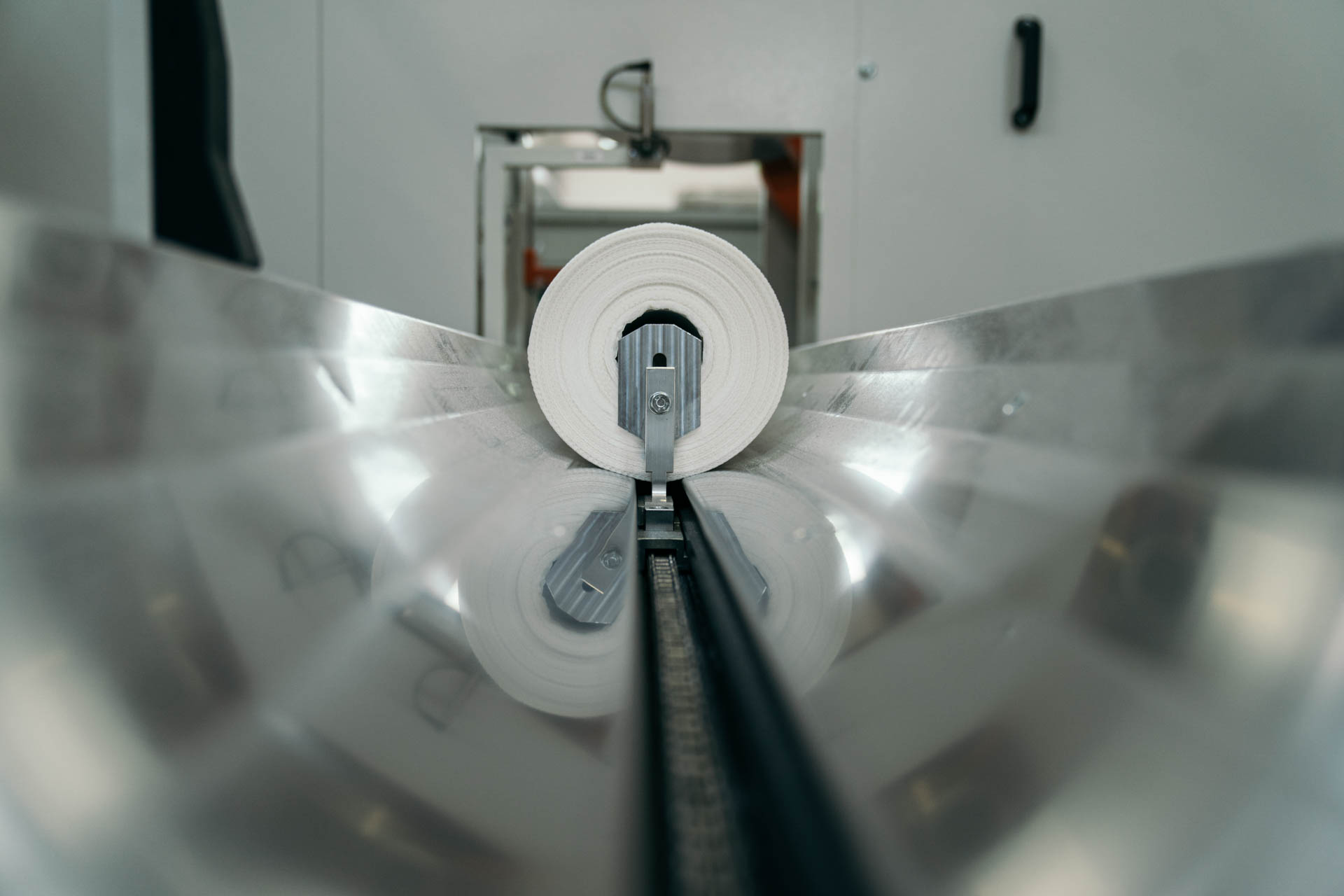

The core maker CWC 160 is a high speed consumer core maker, the glue and lubrication are precisely applied via a drum systeml, the winding belt is servo driven for stable core formation while the cutting is achieved by a servo-controlled saw system.

- Max Speed 160 m/min

- Max Cycles 55 / min

- Core Pi 30-60 mm

- Extruder glue application

- Single ply core capable

- Perfume unit (option)