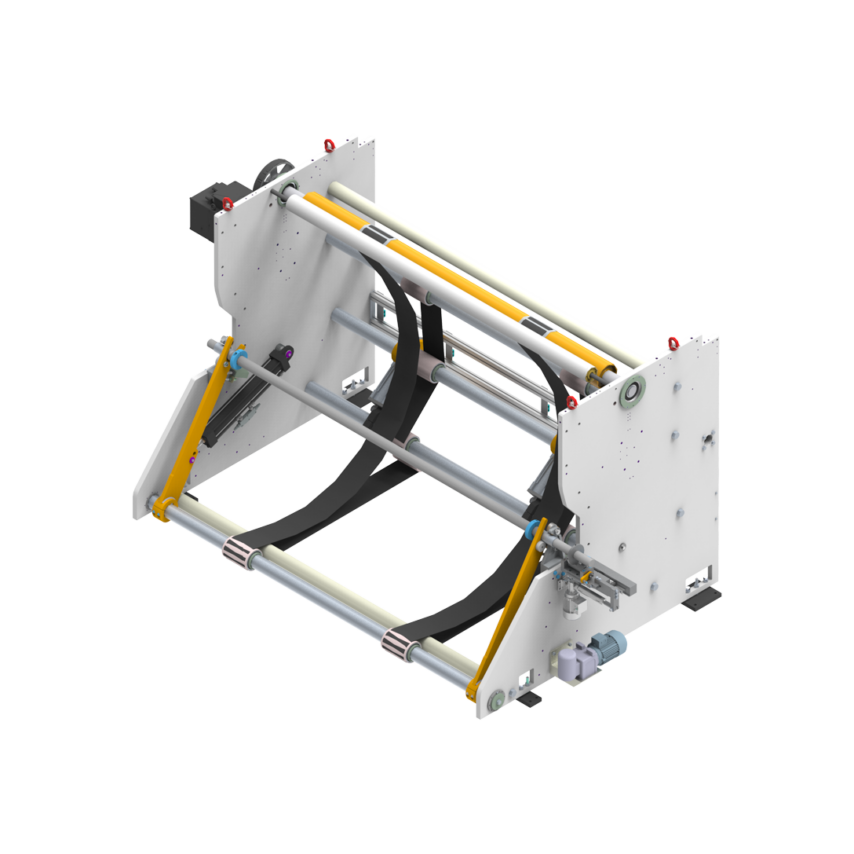

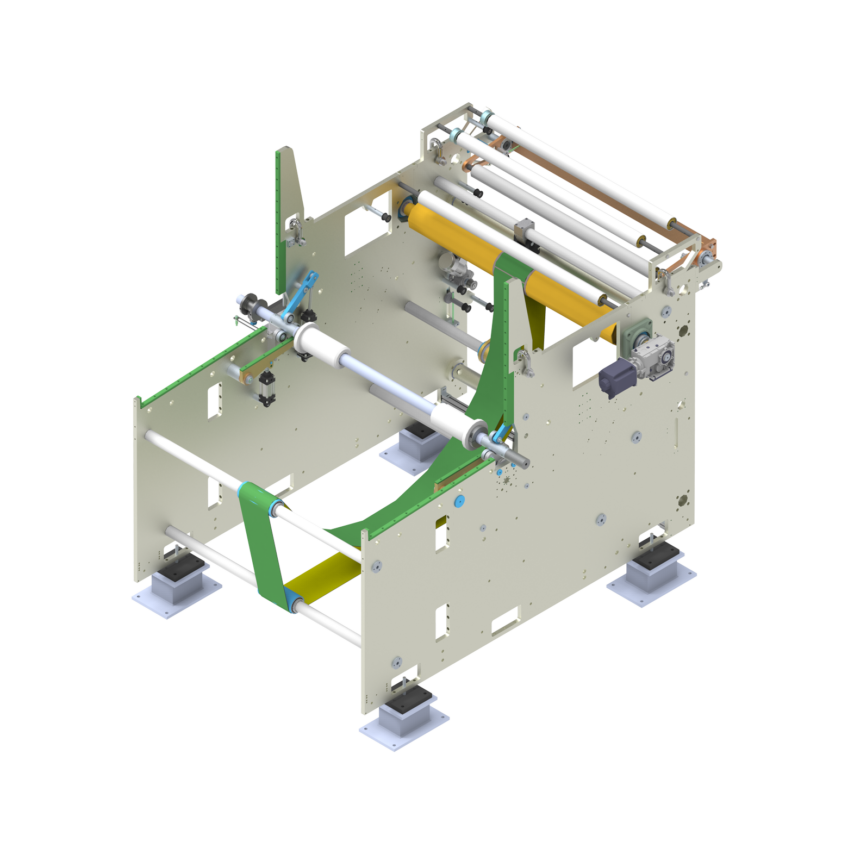

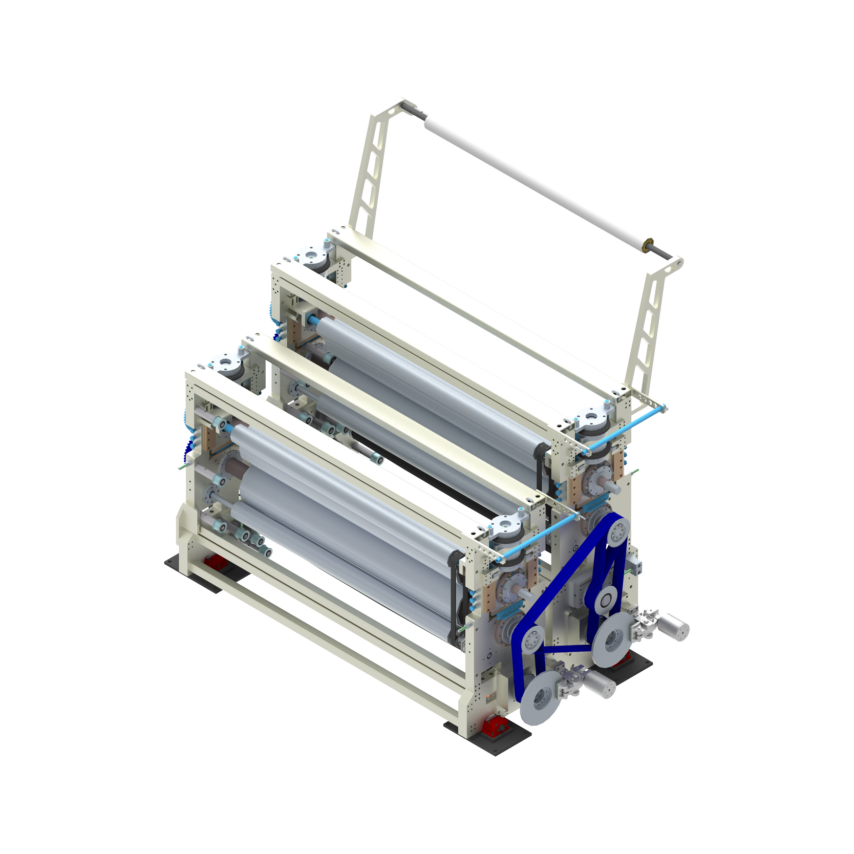

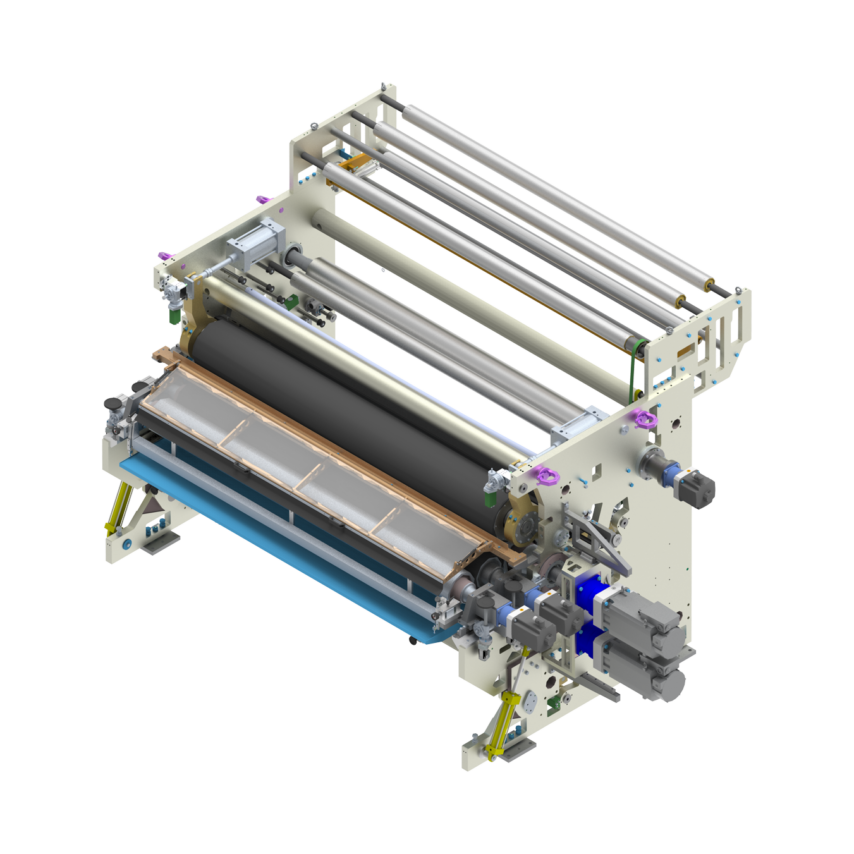

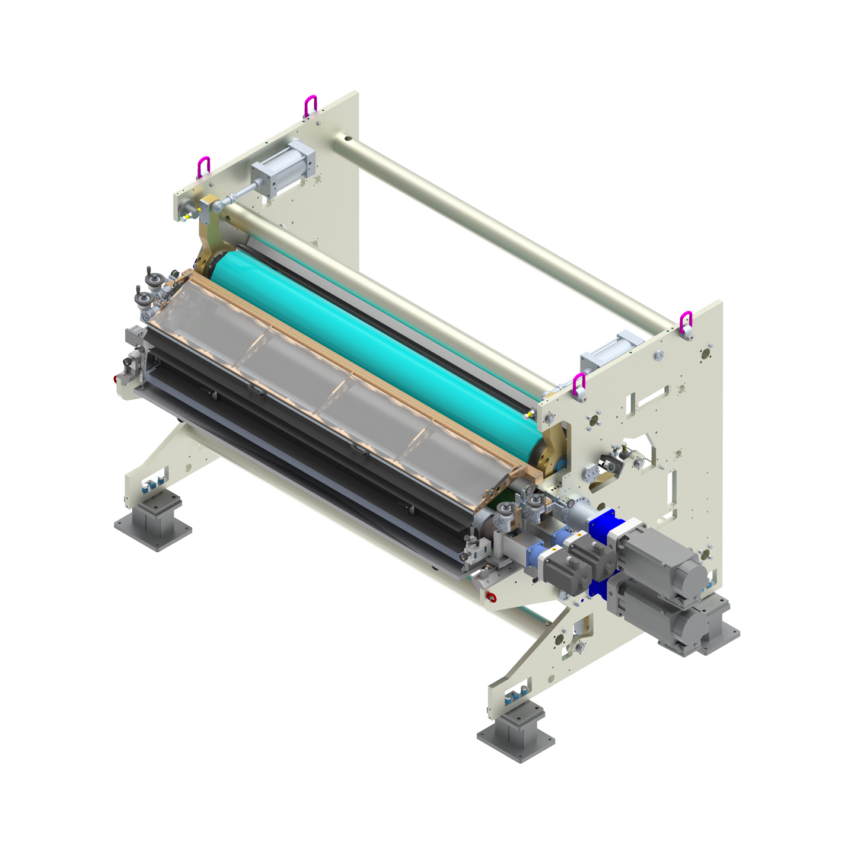

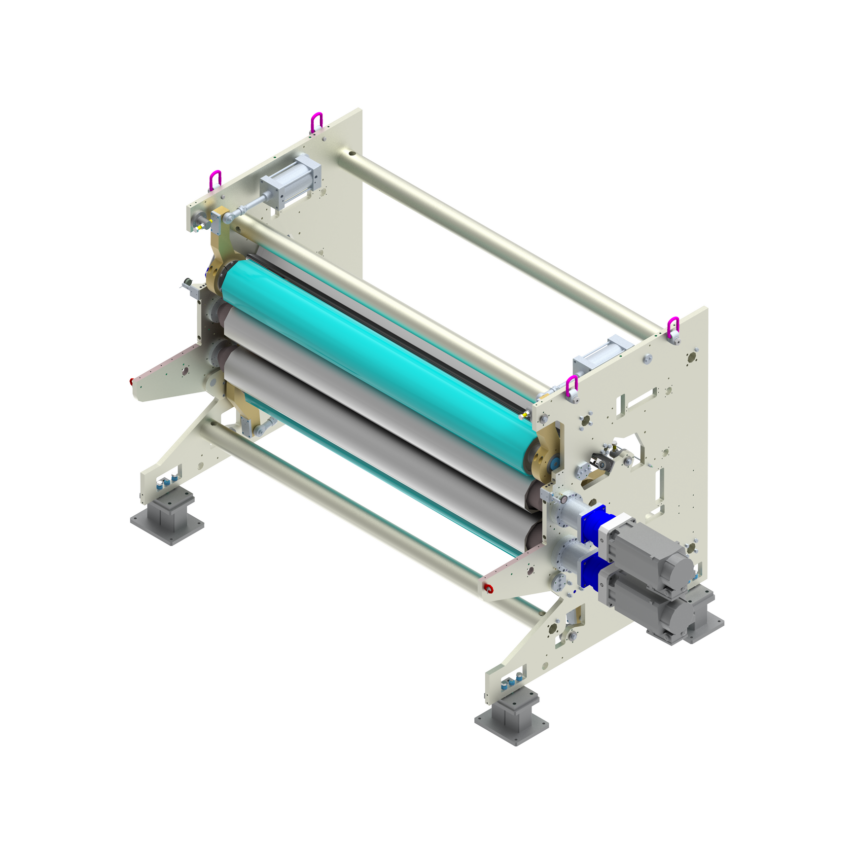

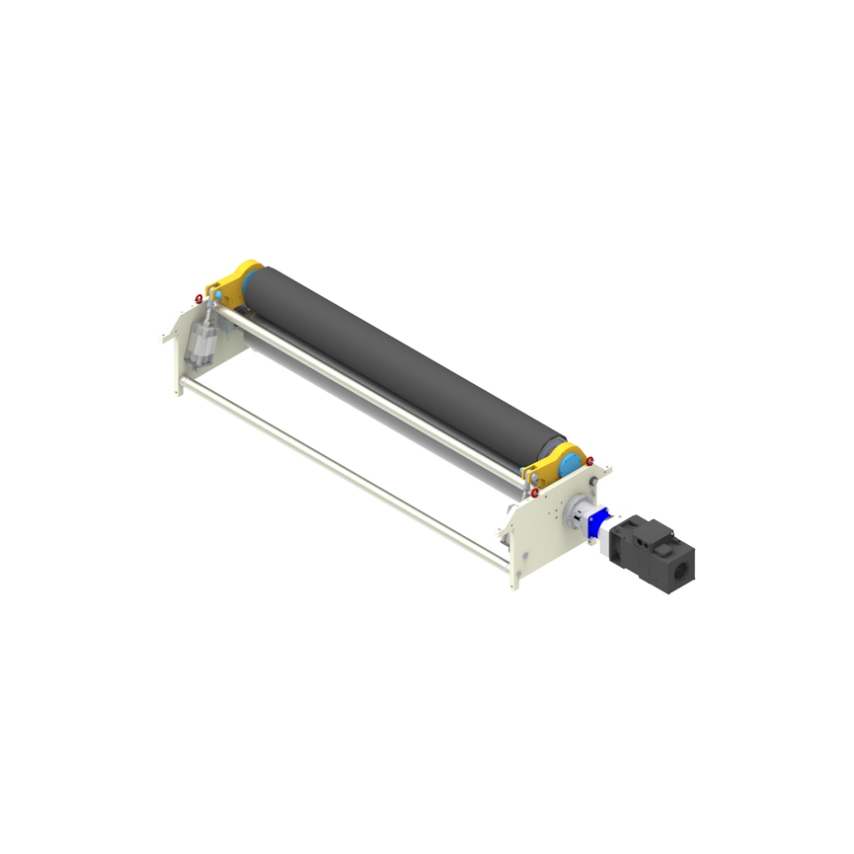

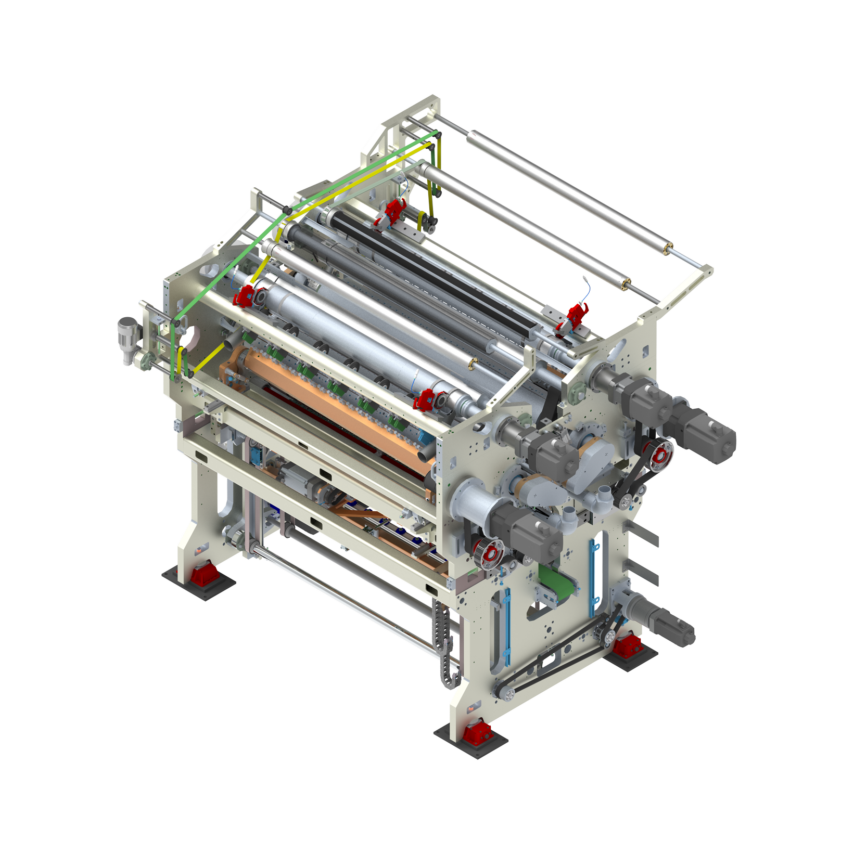

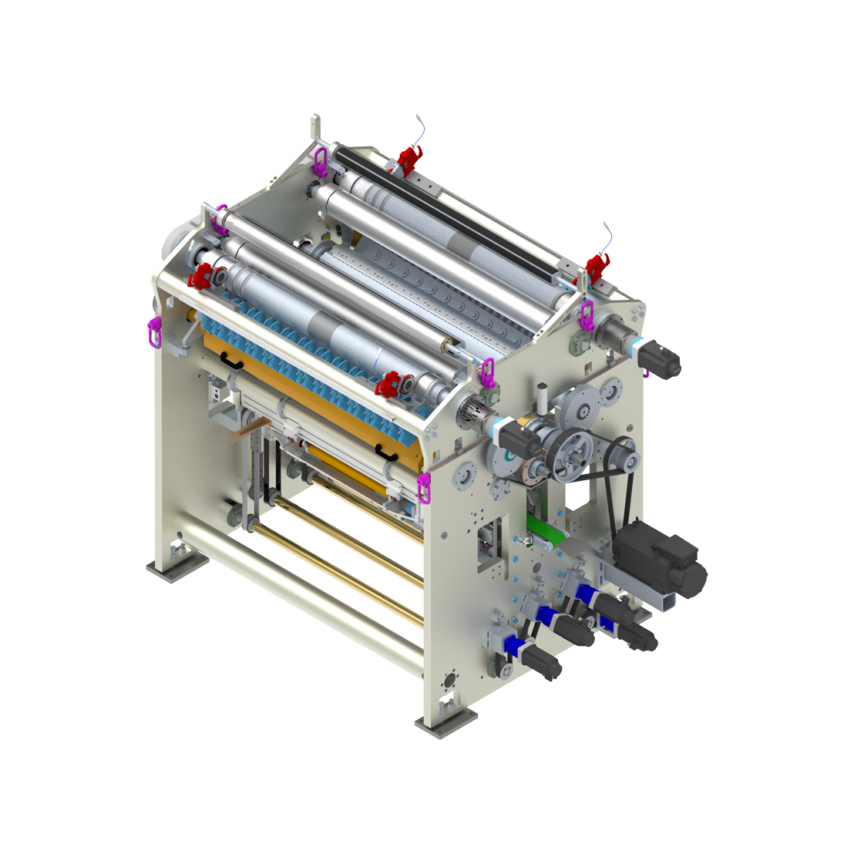

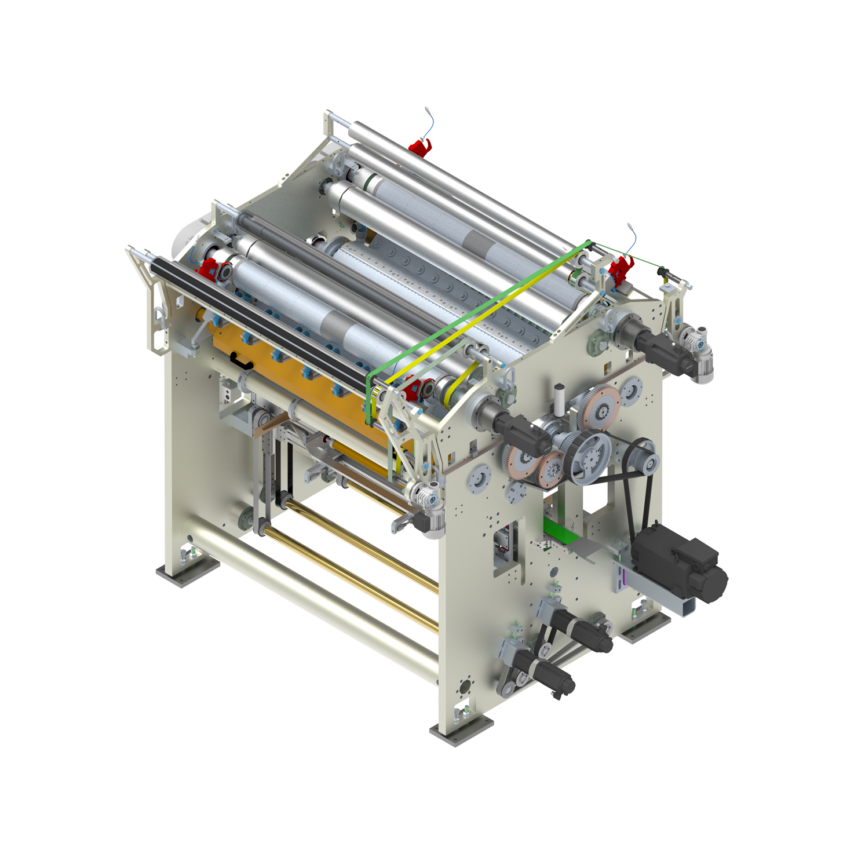

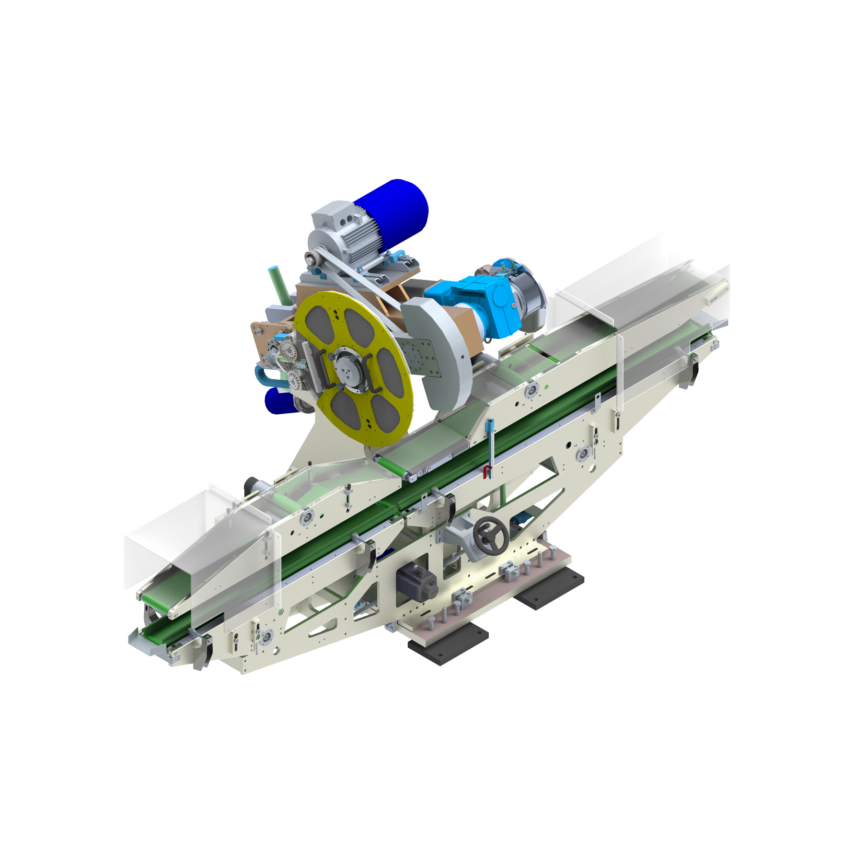

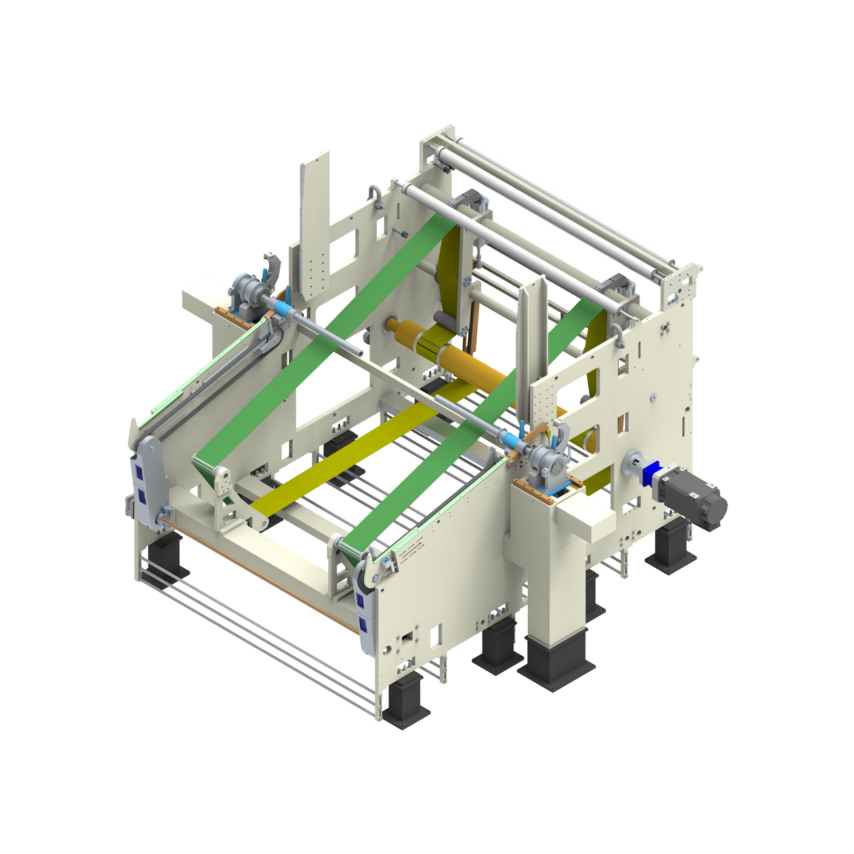

BD 30

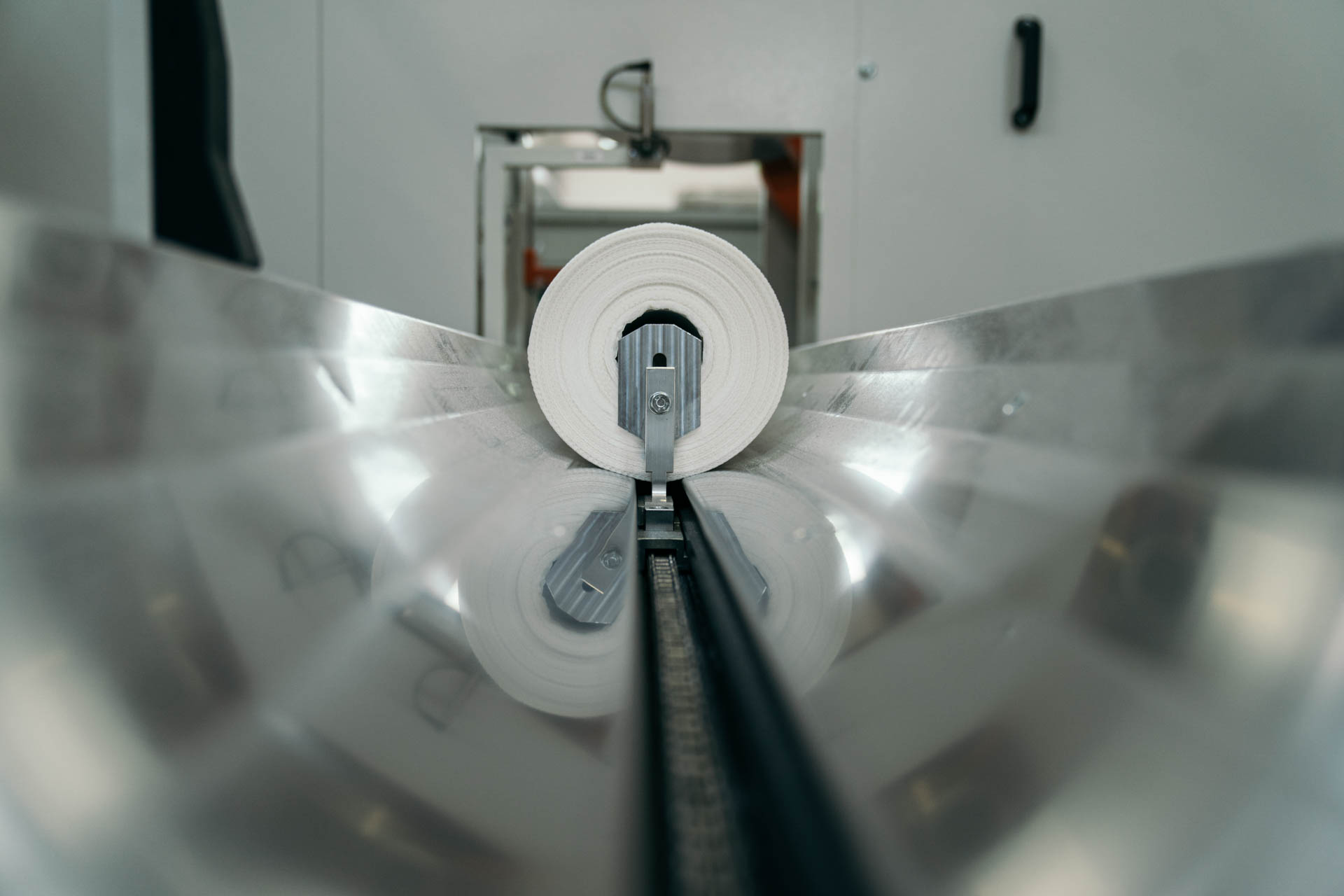

The BD 30 unwinder are custom developed to support pope rolls directly form paper mill.

- Max workings speed 700 m/min

- Servo Driven

- Tension control by Dancer roll or Load cell (option)

- Supported ⌀ up to 3000 mm

- Paper width up to 3650 mm

- Max Reel Weight up to 6500 Kg

- Reel support: Pope Roll

- Reel Loading: overhead crane

- Custom Design on request