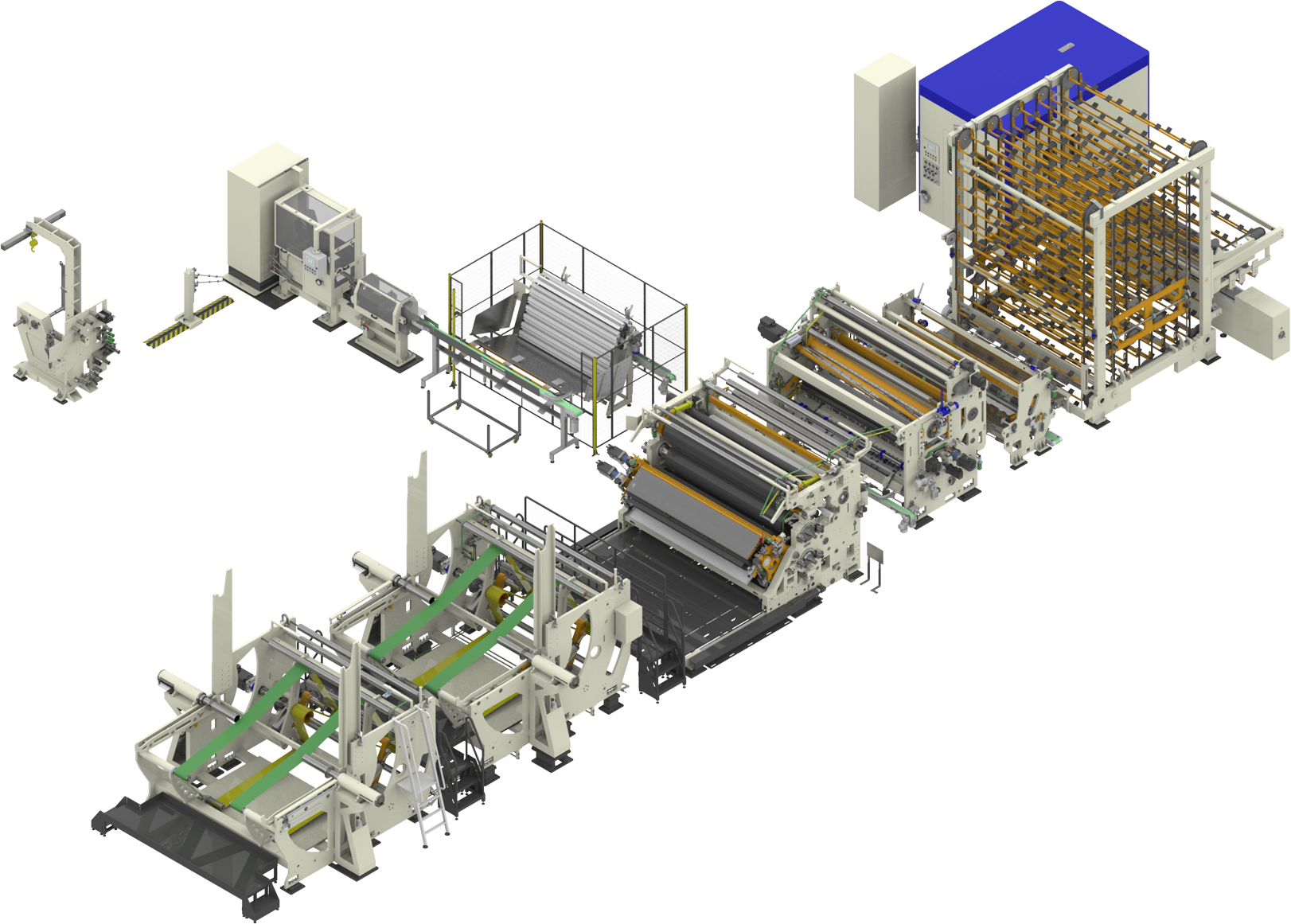

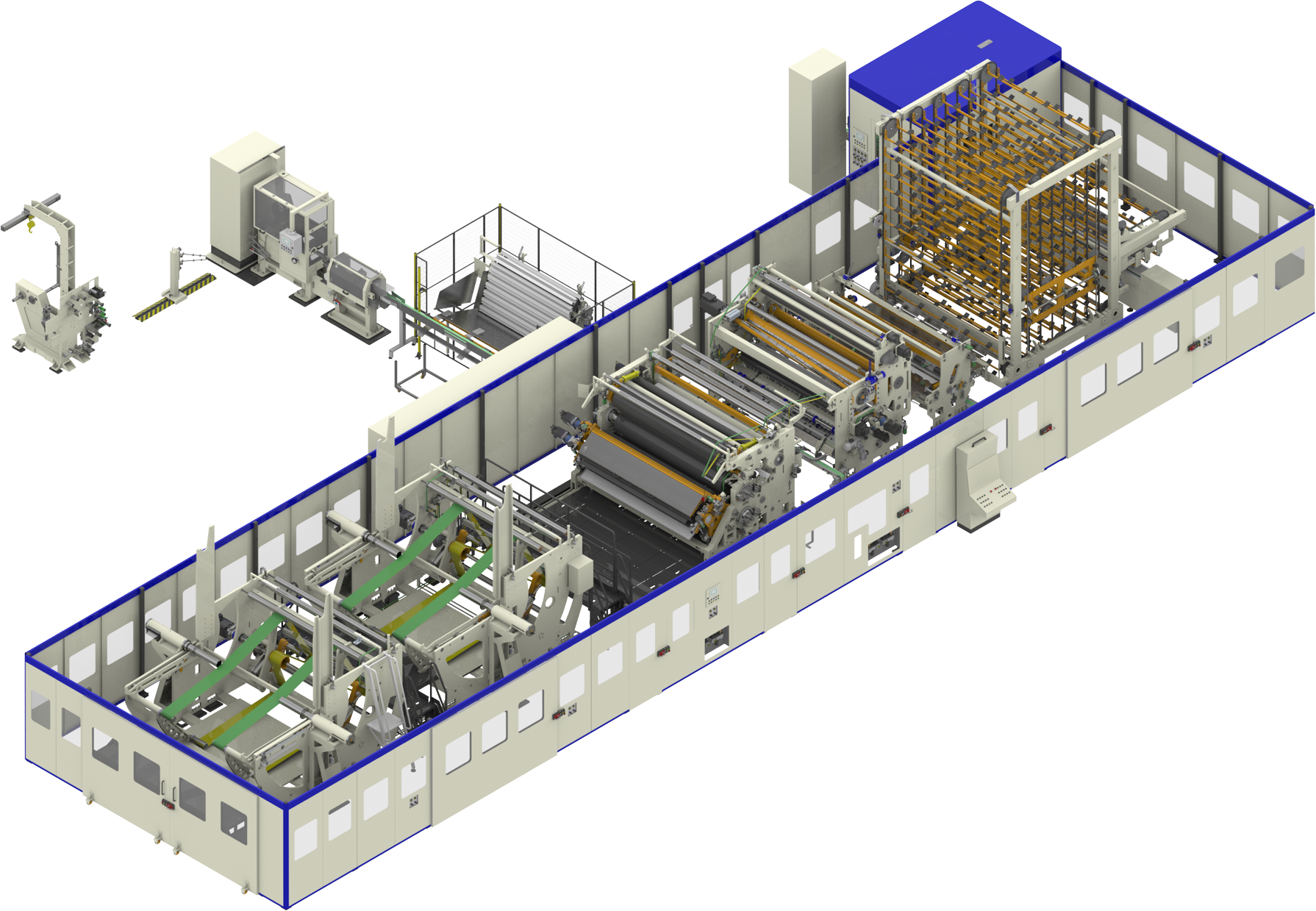

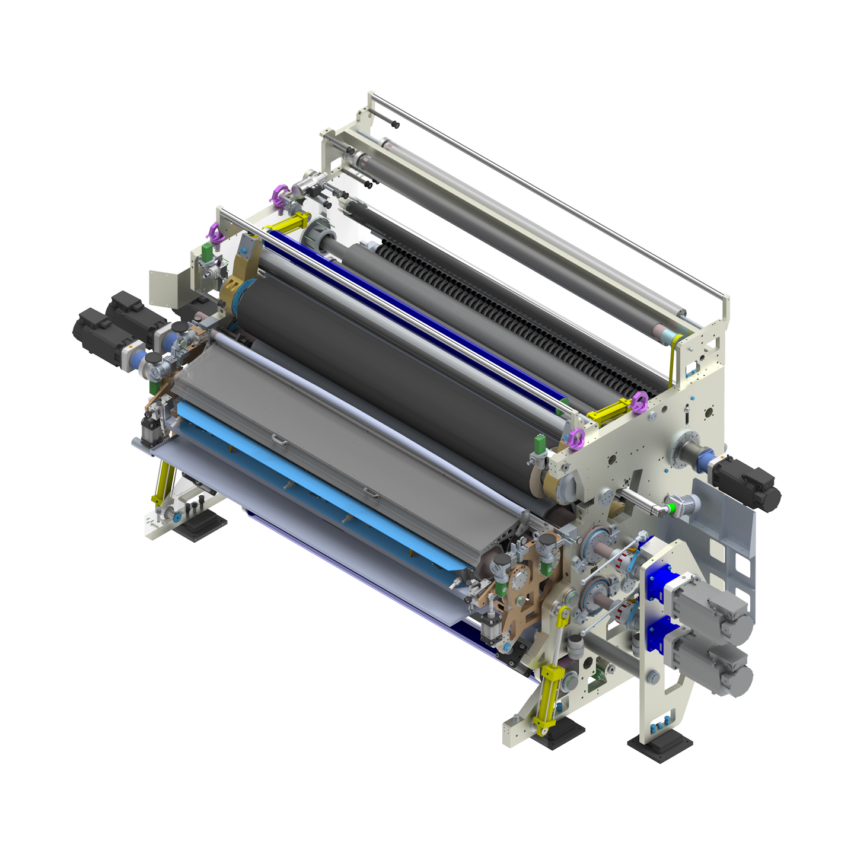

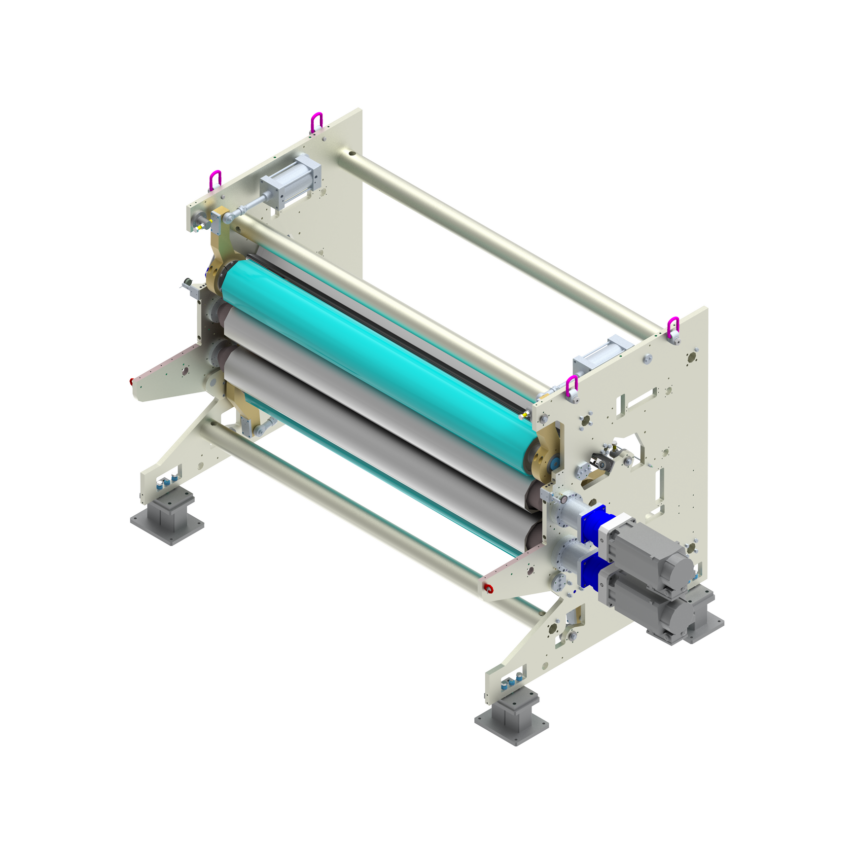

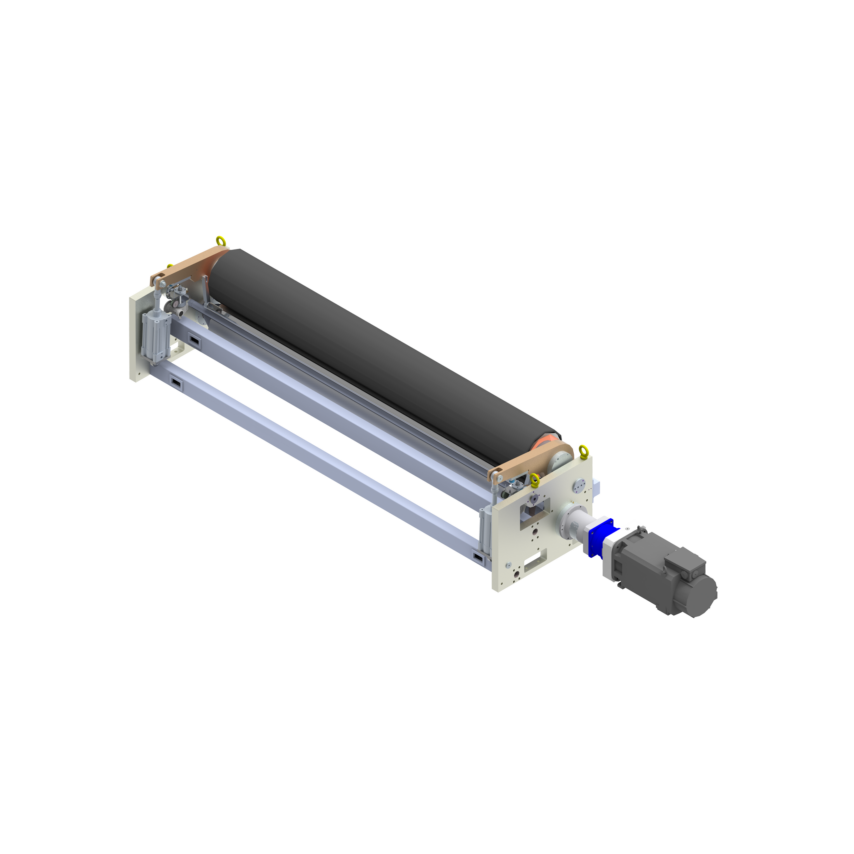

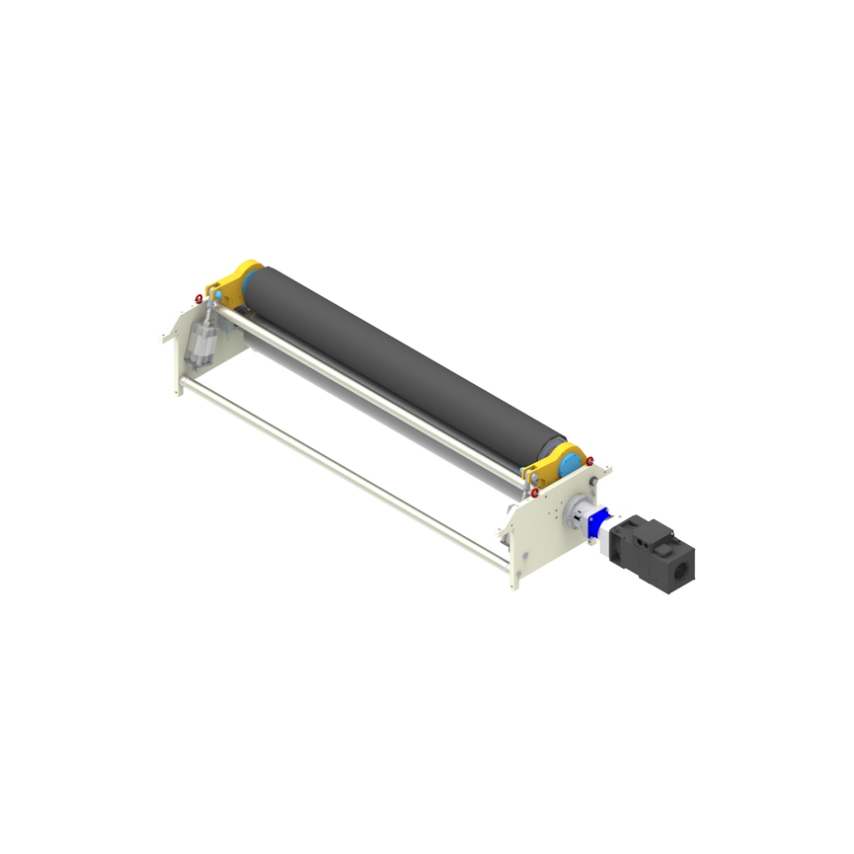

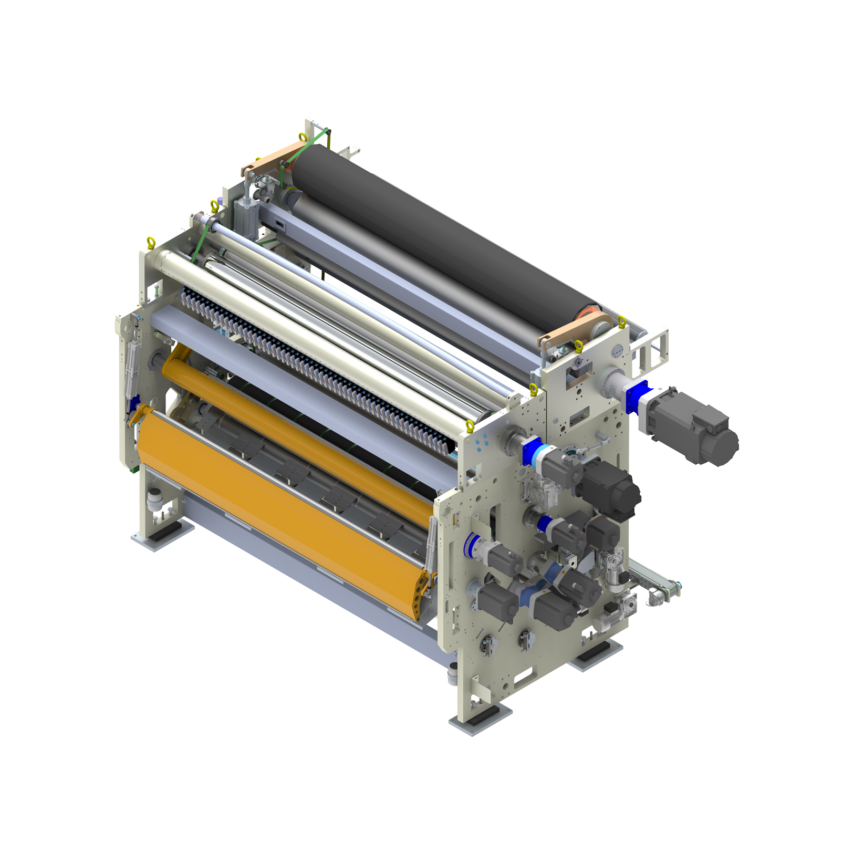

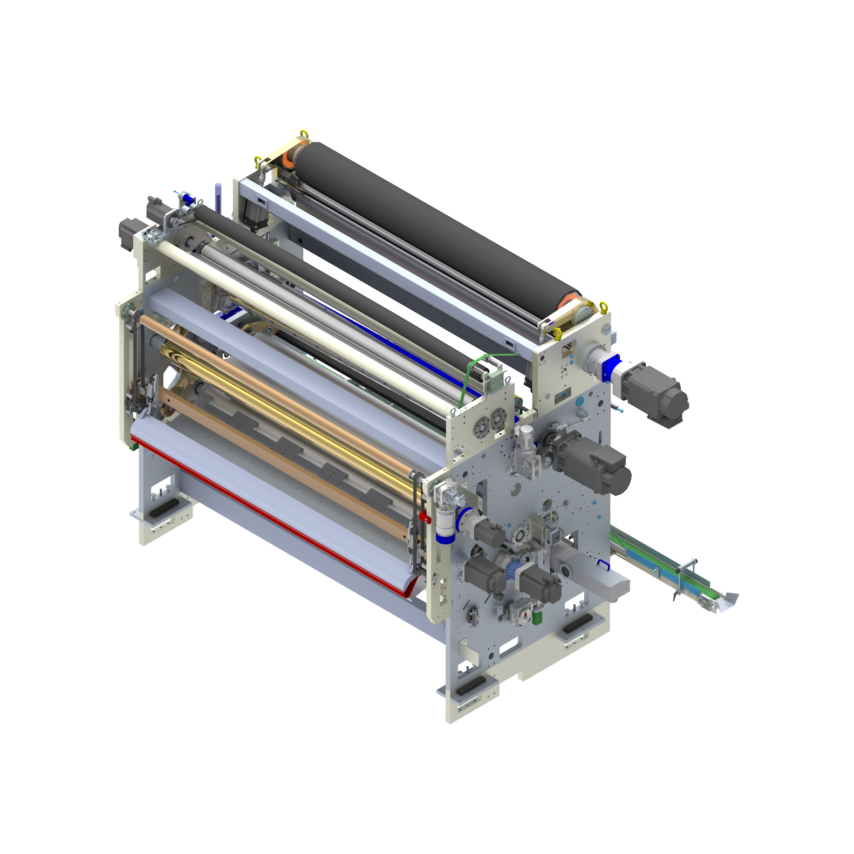

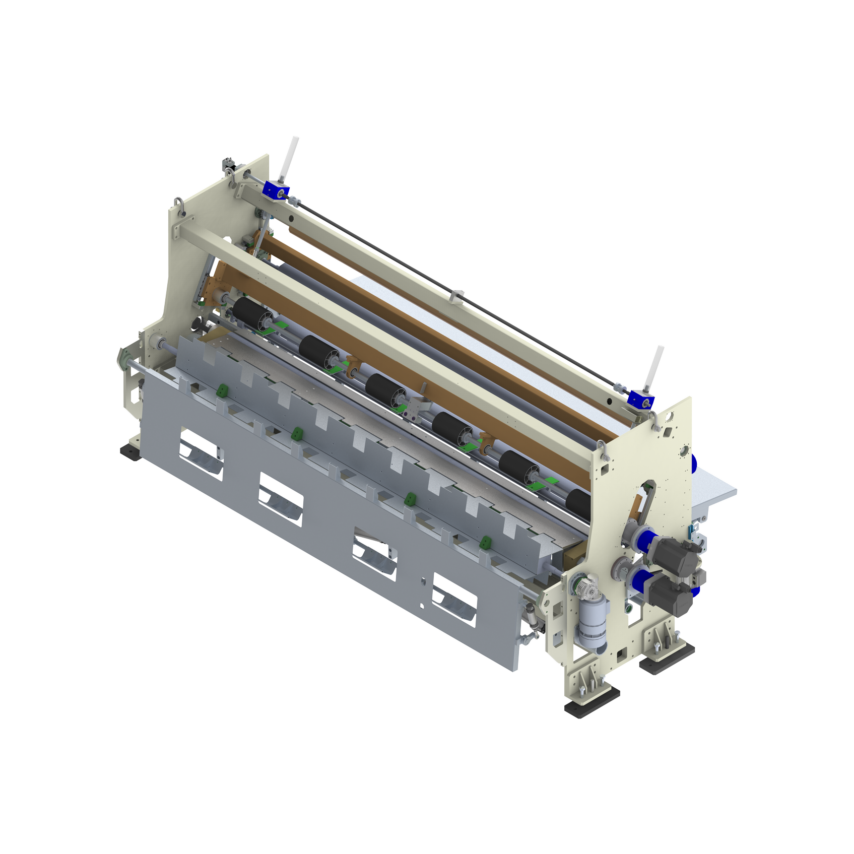

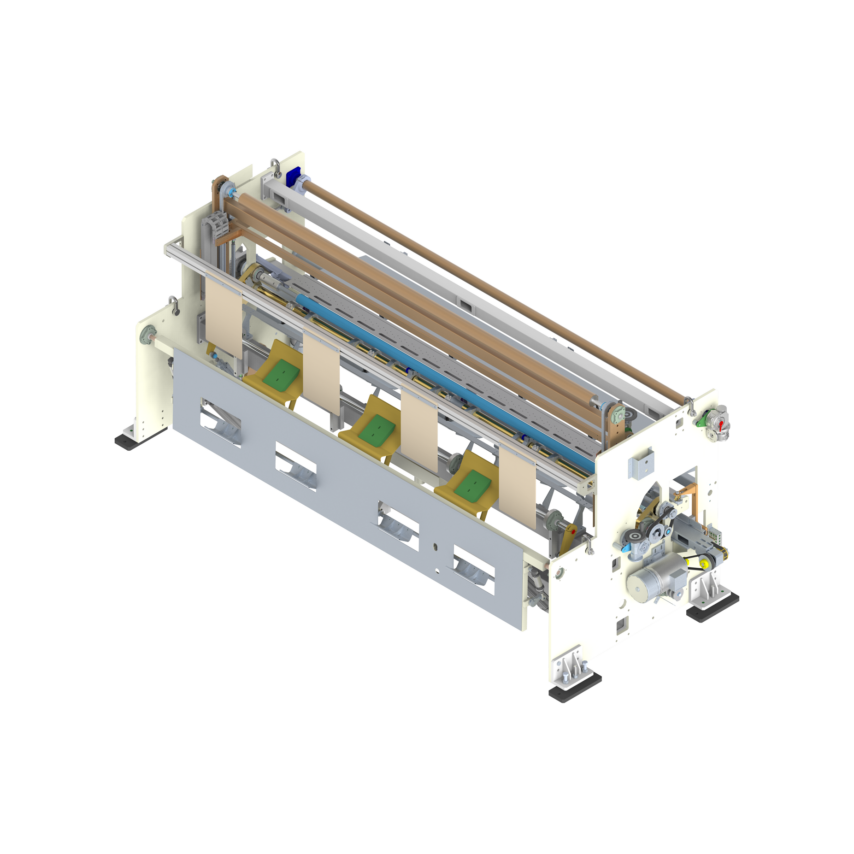

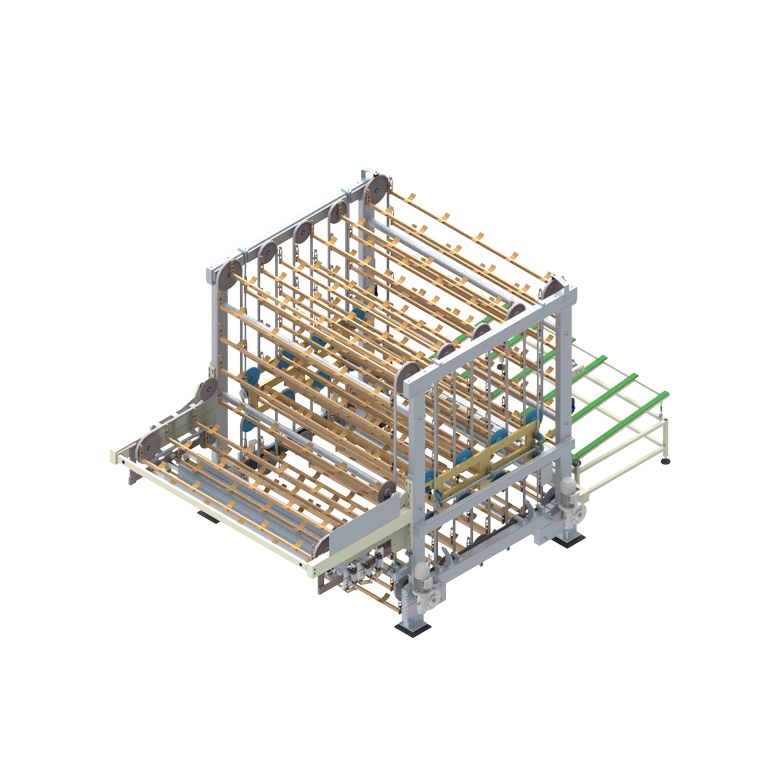

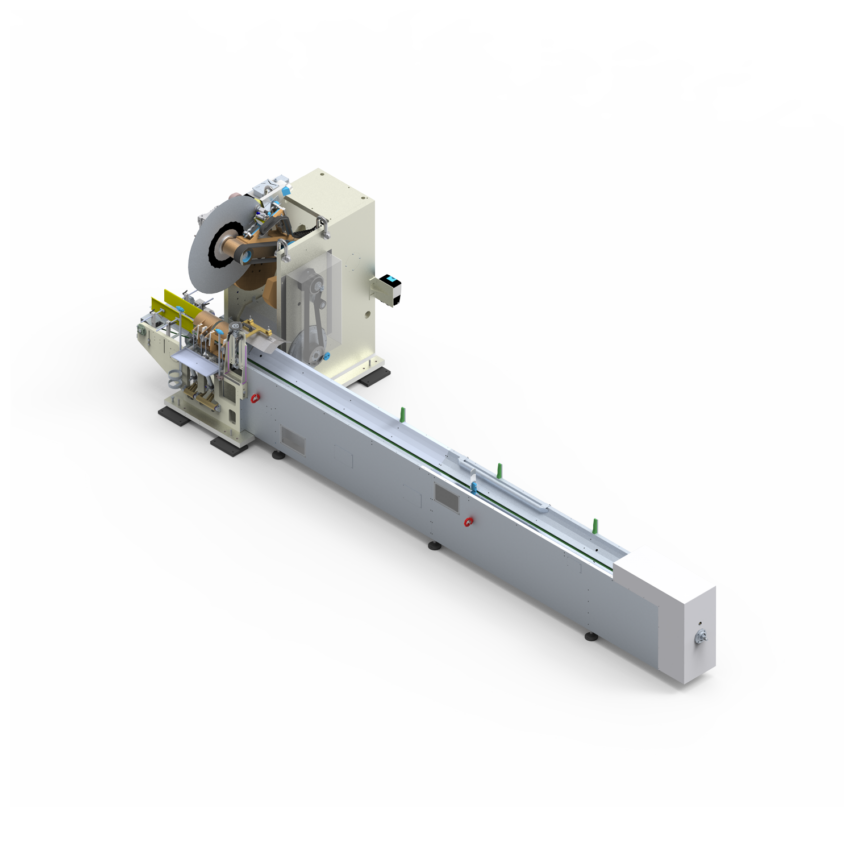

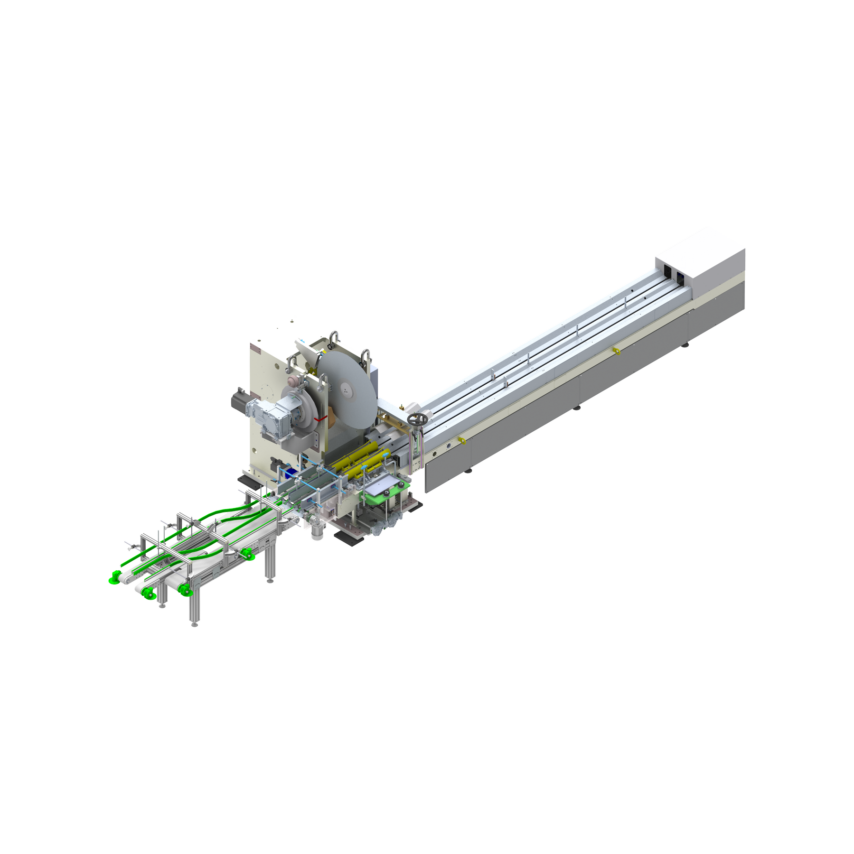

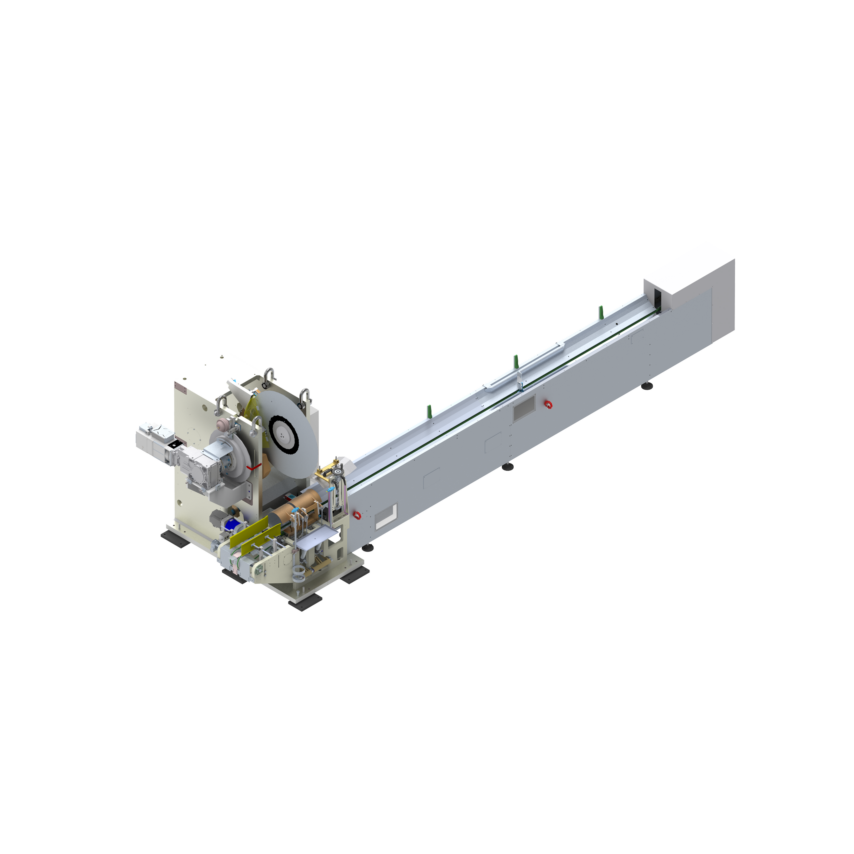

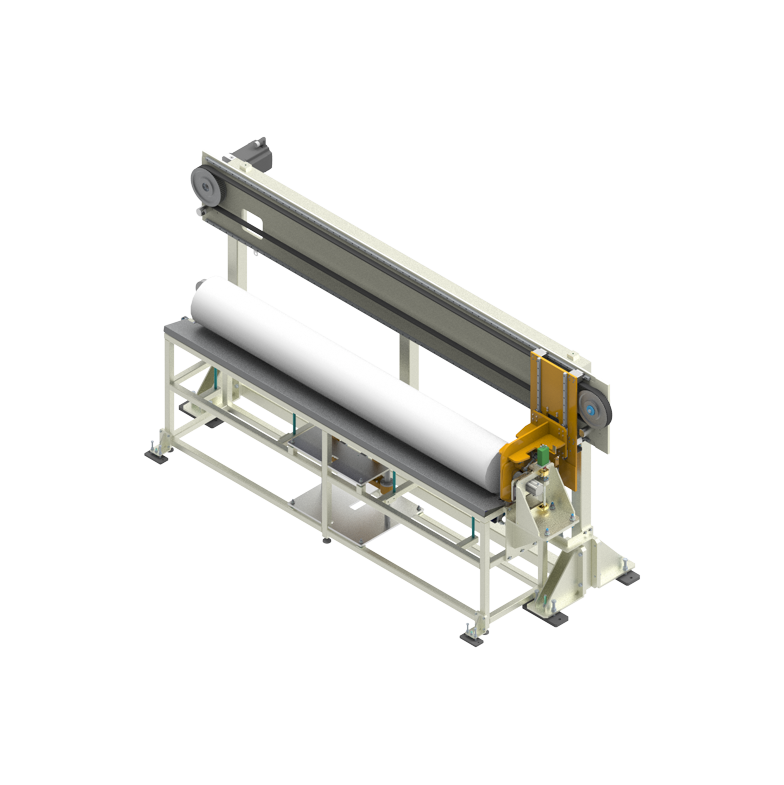

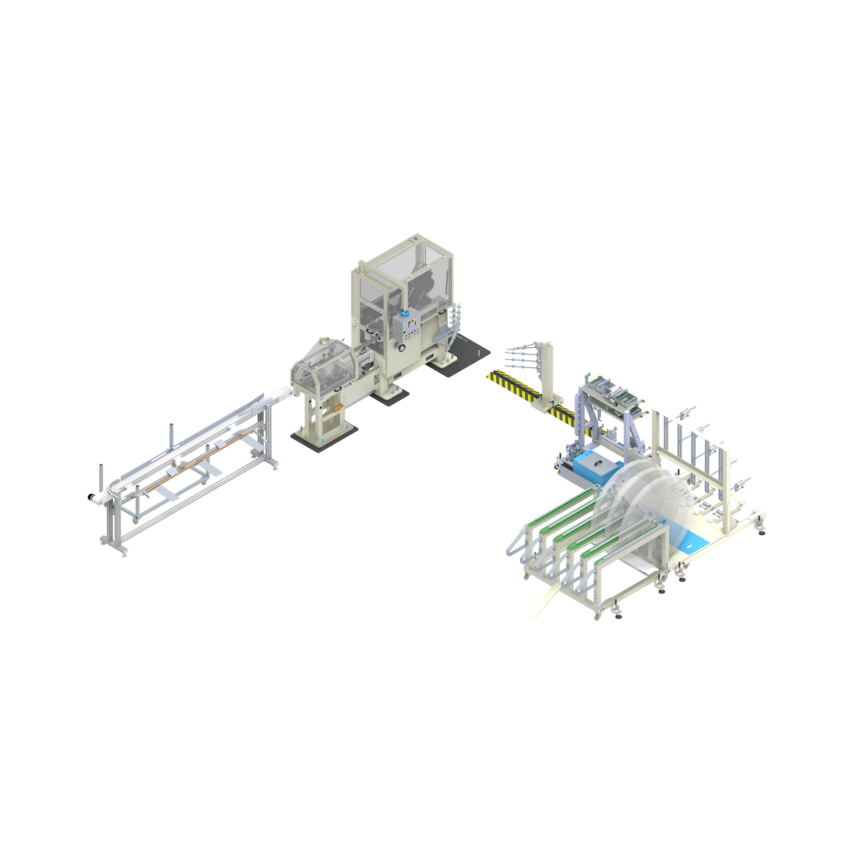

CWC 60i

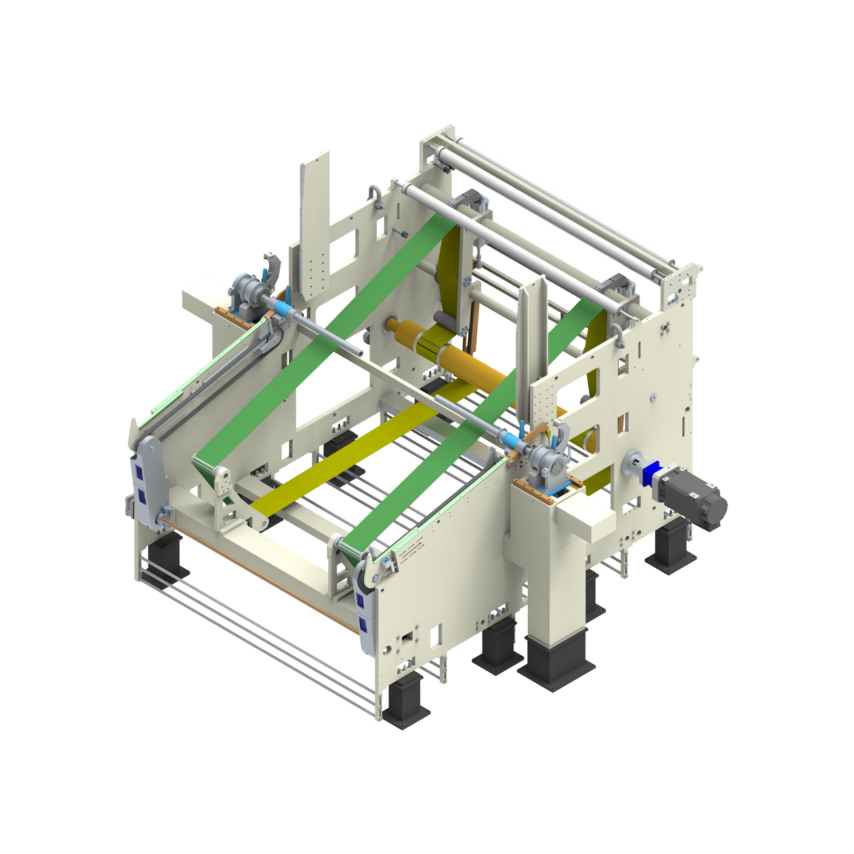

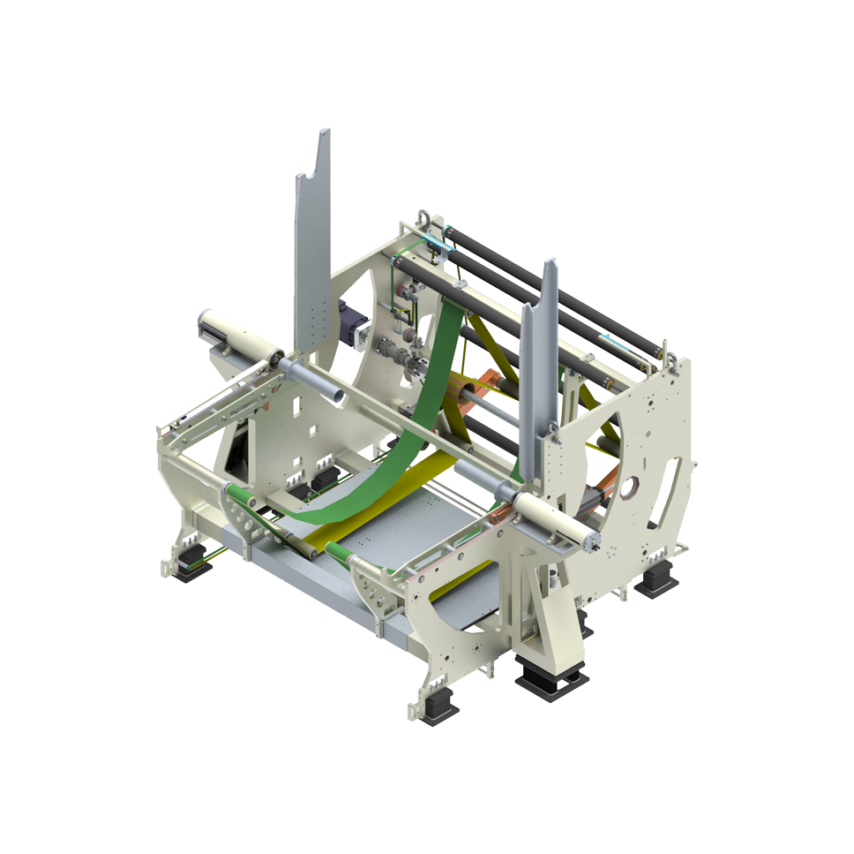

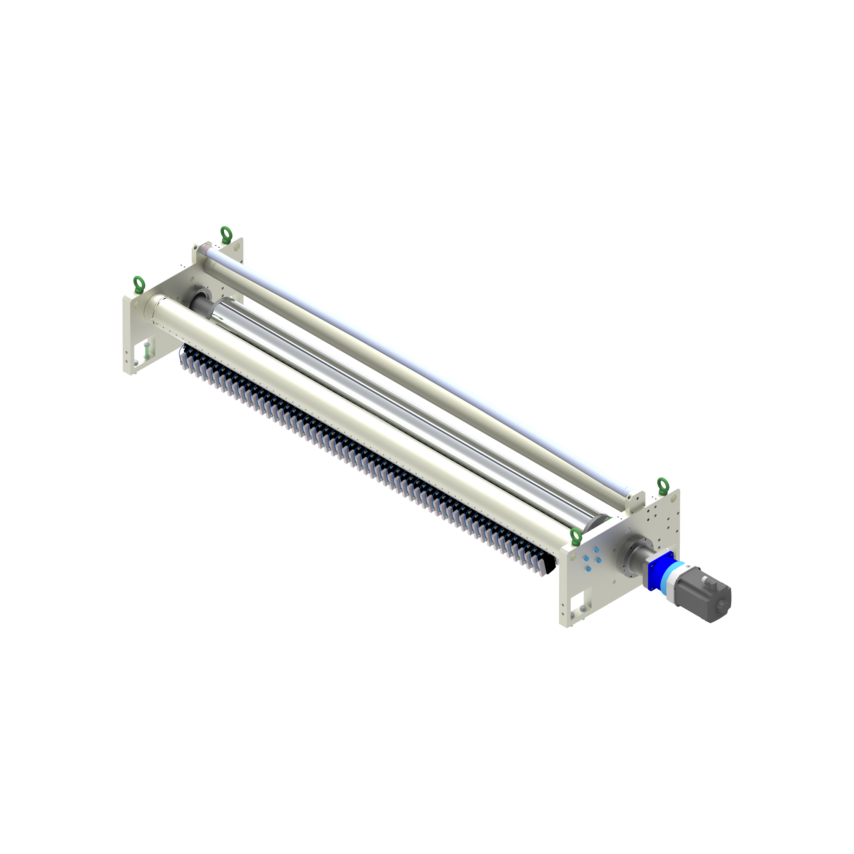

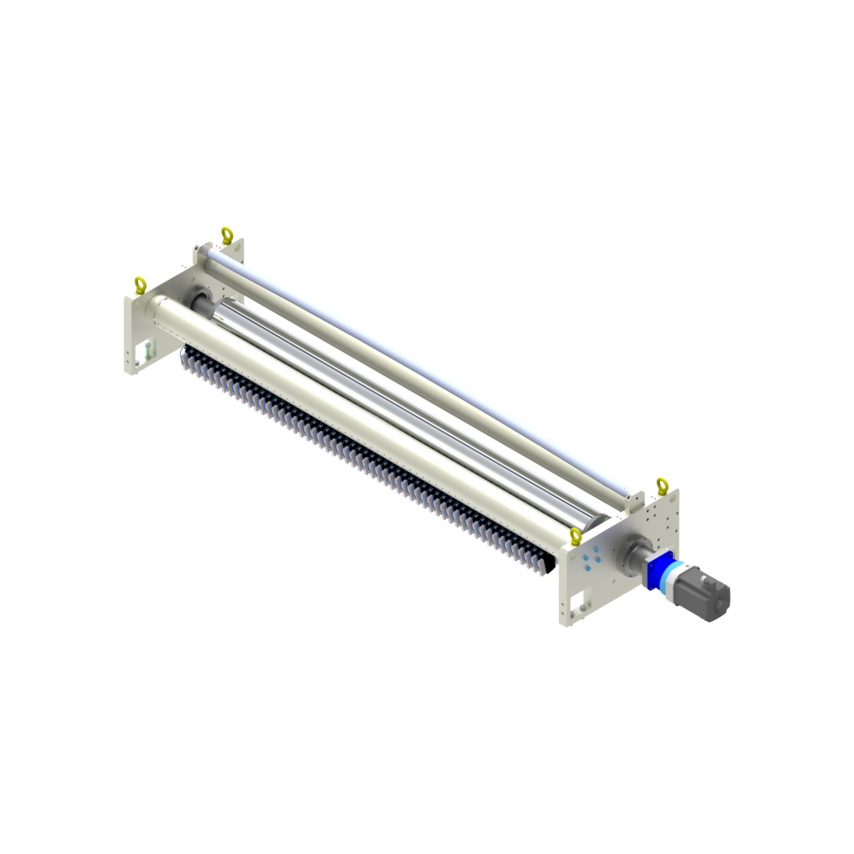

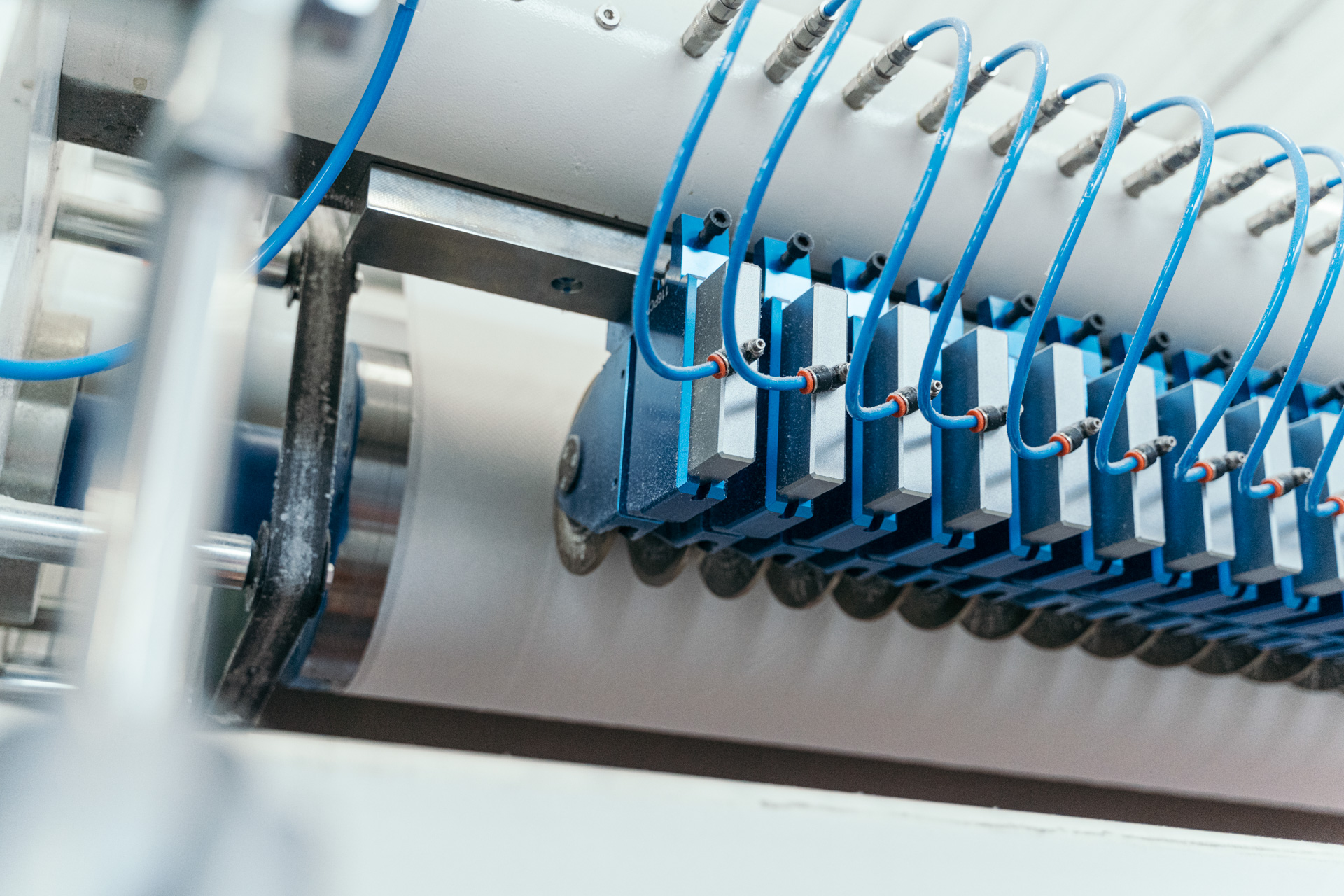

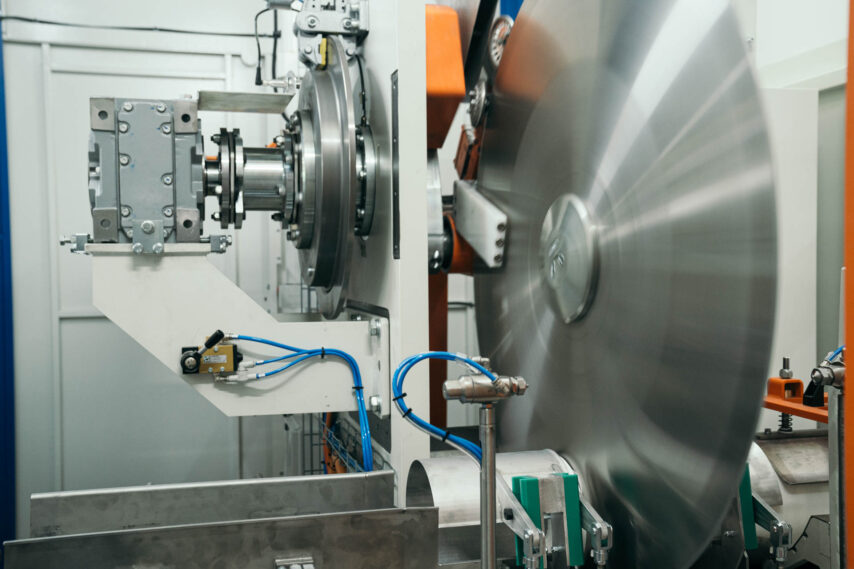

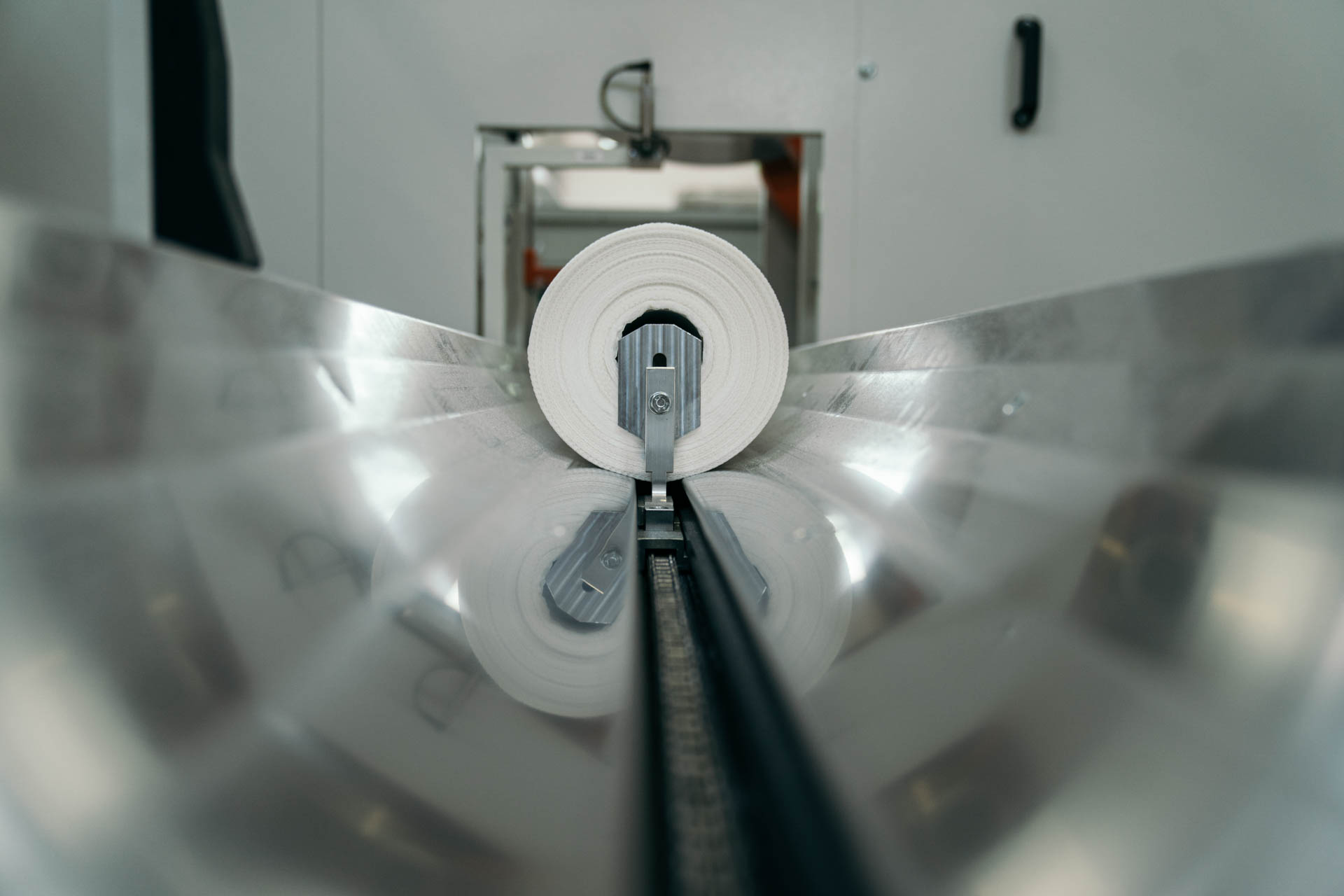

The core maker CWC 60i is a robust industrial core maker, the glue is independently managed for each ply while the first ply pass by a solid lubrication system, the cutting is achieved by a servo-controlled saw system which allow to operate up to 5 plies cores.

- Max Speed 60 m/min

- Max Cycles 20 / min

- Core Pi 30-90 mm

- Up to 5 plies

- 20 mm LoCore (option)